For many enterprises, teams still wait for machines to show signs of failure or stop working altogether before taking action. Unplanned equipment failures cost manufacturers in the U.S. alone over $50 billion annually, making them one of the most expensive and preventable problems enterprises face today. Over time, reactive fixes become costly, both financially and strategically. Maintenance teams are left responding to issues rather than preventing them. This firefighting model, while familiar, is no longer sustainable in high-output environments.

Edge AI in predictive maintenance is emerging as a practical alternative for enterprises looking to change this narrative. By enabling real-time condition monitoring directly at the source, edge AI allows organizations to detect potential failures before they become disruptions. At least 50% of leading enterprises are already transitioning to edge AI for predictive maintenance, leaving behind unreliable traditional, reactive methods.

At Intellvon, our pre-vetted AI experts have hands-on expertise in developing predictive maintenance systems for leading enterprises with edge AI. Through our years of experience, we have delivered measurable ROI for businesses through this process, reducing their maintenance costs and enhancing customer loyalty. In this blog, we will break down exactly how we build such a system from the ground up.

Why Enterprises Are Switching to Edge-AI-Based Predictive Maintenance

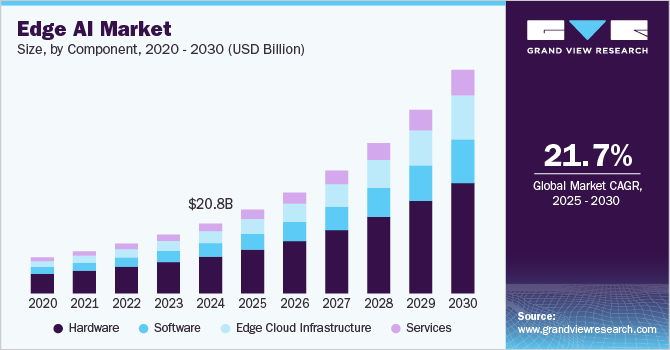

The global Edge AI market is valued at around $20.78 billion and is expected to reach about $66.47 billion by 2030, growing at an annual rate of 21.7% from 2025 to 2030. Edge AI is becoming a key technology for real-time, on-device applications like predictive maintenance. It helps make faster decisions, reduce downtime, and improve efficiency without depending fully on the cloud. Around 50% of enterprises worldwide are already using edge AI for robust predictive maintenance solutions, and this number is expected to grow at an exponential rate.

Key Market Drivers:

- Real-time data processing: Industries like manufacturing, healthcare, telecom, and autonomous vehicles need quick data analysis near the source to improve operations and safety. Edge AI processes data locally for faster responses.

- Privacy and security: By processing sensitive data locally, Edge AI reduces data transmission to the cloud, improving privacy and lowering the risk of cyber threats, especially in healthcare, finance, and industrial sectors.

- Connectivity issues: In areas with poor internet access, like remote industrial sites, Edge AI ensures continuous operation by processing data locally, without needing the cloud.

- Cost savings: Reducing the amount of data sent to the cloud cuts bandwidth and processing costs. Edge AI uses local resources, saving businesses money, especially those managing large IoT networks.

- Growth of IoT devices: The increase in connected devices generates vast amounts of data. Edge AI processes this data locally or nearby, improving system efficiency.

- Edge and cloud synergy: Combining local Edge AI processing with cloud analytics optimizes resources, handling immediate decisions at the edge while the cloud manages complex tasks.

- Tech advancements: Better hardware and software for Edge AI are making it easier for businesses to deploy and gain higher performance from these solutions.

What Is Predictive Maintenance?

Predictive maintenance (PdM) is a data-driven approach that allows enterprises to anticipate equipment failures before they happen. By monitoring asset health in real time through IoT sensors, such as tracking vibration, temperature, pressure, and sound, PdM enables maintenance actions based on actual machine conditions rather than fixed schedules.

This approach helps reduce unplanned downtimes, avoid unnecessary part replacements, and extend asset lifespan, leading to lower operational costs and improved productivity.

How Predictive Maintenance Works for Enterprises

1. Real-Time Equipment Monitoring

Sensors installed on industrial equipment continuously track performance metrics. These readings help detect small irregularities, such as increased vibration or overheating, that may indicate emerging issues.

2. Data Transmission to the Cloud

Traditionally, this data is sent to cloud platforms where machine learning models analyze patterns, identify anomalies, and predict future failures or maintenance needs.

3. Maintenance Planning Based on Predictions

Once risks are detected, alerts are generated to help teams plan maintenance proactively. This minimizes unexpected breakdowns, improves uptime, and makes better use of resources.

The Gaps in Traditional Cloud-Based Predictive Maintenance

1. Latency in the Cloud

Cloud-based systems introduce delays between data collection and response. In time-sensitive environments, this can be costly.

2. Dependence on Constant Connectivity

Remote or industrial sites often struggle with reliable internet access, limiting real-time cloud communication.

3. Delayed Sensor-to-Insight Loop

Transmitting high-frequency data to the cloud can slow the insight generation process, reducing responsiveness.

4. High Bandwidth and Operating Costs

Continuous raw data transmission increases bandwidth usage, leading to higher cloud storage and processing costs.

Edge AI as the Missing Layer

To overcome these challenges, enterprises are integrating Edge AI, which brings real-time intelligence directly to the equipment, thereby reducing latency, bandwidth needs, and reliance on constant connectivity.

The Role of Edge AI in Next-Gen Predictive Maintenance

Many enterprises rely on predictive maintenance systems that send large volumes of sensor data to cloud servers for analysis and processing. While this approach marked a step forward from purely reactive models, it often introduces a delay between data capture and the delivery of insights. In high-speed industrial operations, even a few seconds of latency can be the difference between normal uptime and a major system failure.

Edge AI is reshaping this process by placing intelligence directly at the point of data generation. Instead of routing every signal through centralized infrastructure, edge-enabled systems perform analysis in real time, right at the equipment level.

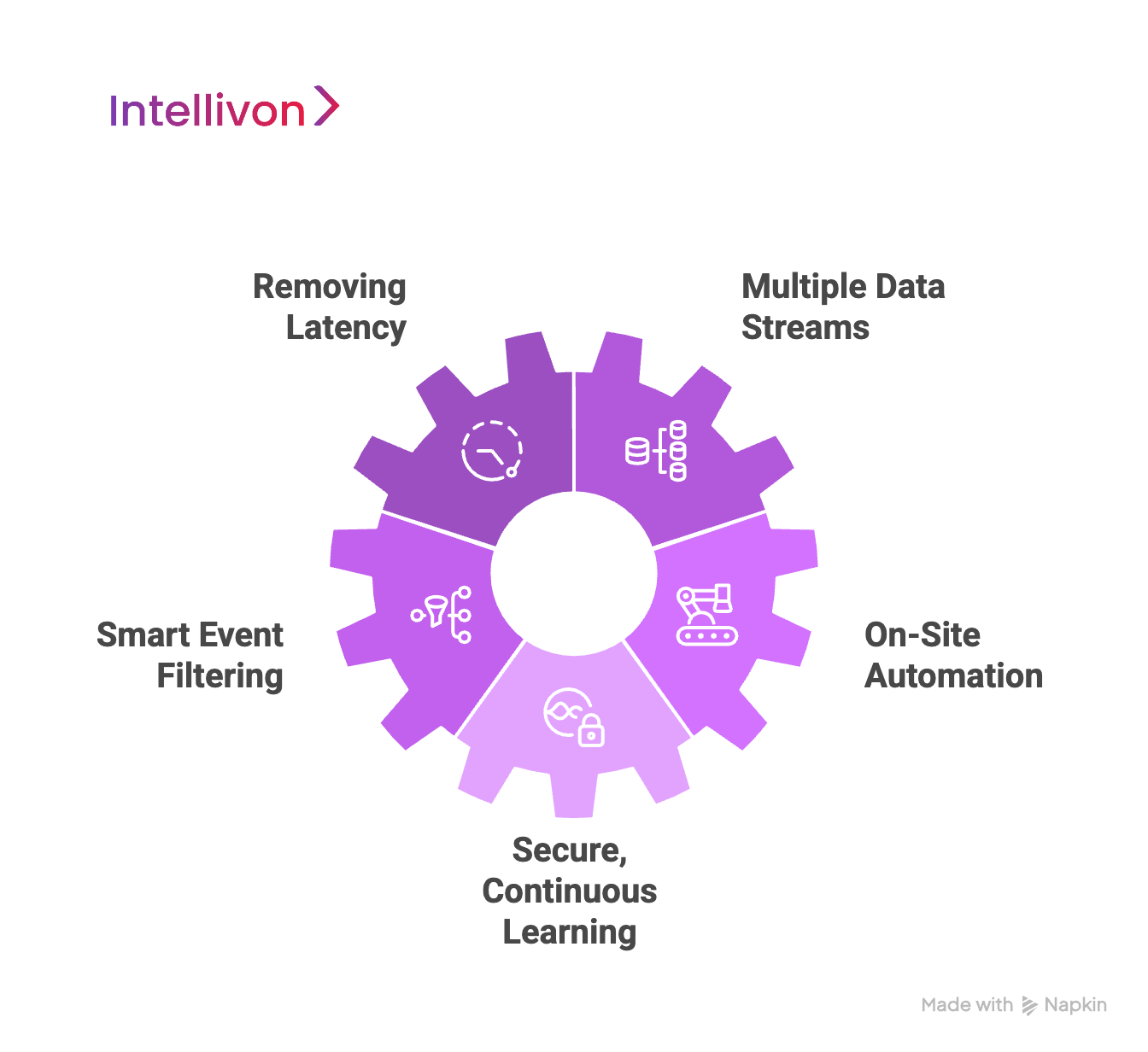

1. Removing Latency

Unlike cloud-based tools that depend on remote processing, Edge AI interprets critical data, such as vibration frequencies, temperature shifts, and acoustic anomalies, on-site. This significantly reduces the time it takes to recognize early signs of mechanical stress or degradation.

When failure indicators are detected in milliseconds rather than seconds, enterprises gain the opportunity to act before problems escalate.

2. Multiple Data Streams

Modern equipment generates a wide array of signals, but evaluating these streams in isolation often leads to partial or misleading insights. Edge AI enables sensor fusion by simultaneously analyzing multiple types of input. By correlating temperature data with vibration trends or acoustic shifts, the system can detect subtle patterns that indicate complex failure modes.

This level of contextual intelligence strengthens both diagnostic precision and early warning capabilities.

3. Smart Event Filtering

Edge AI does more than just process data quickly. It also ensures that only meaningful, actionable events are passed along to central systems. By filtering sensor streams on-device, the platform removes irrelevant data and prioritizes critical anomalies. As a result, enterprise teams receive clear, focused alerts without having to sift through overwhelming amounts of raw information.

This also leads to more efficient use of bandwidth and cloud resources.

4. On-Site Automation

In advanced configurations, Edge AI systems can execute local responses to urgent events. These include automatic shutdowns, rerouting workflows, or sending signals to adjacent machines. Such actions happen within a closed loop, often without the need for cloud communication or human intervention.

This immediate feedback cycle adds an extra layer of safety and reliability to critical operations, especially in facilities where uptime is non-negotiable.

5. Secure, Continuous Learning

Over time, Edge AI platforms can refine their understanding of each machine’s unique operating patterns. Through on-device learning or secure federated training models, they evolve without exposing sensitive data to external networks. This adaptive intelligence allows predictive systems to become increasingly accurate while respecting enterprise security protocols and data residency requirements.

As predictive maintenance enters its next phase, Edge AI stands out not only for its speed and autonomy but also for its ability to align tightly with the operational realities of large-scale enterprise environments.

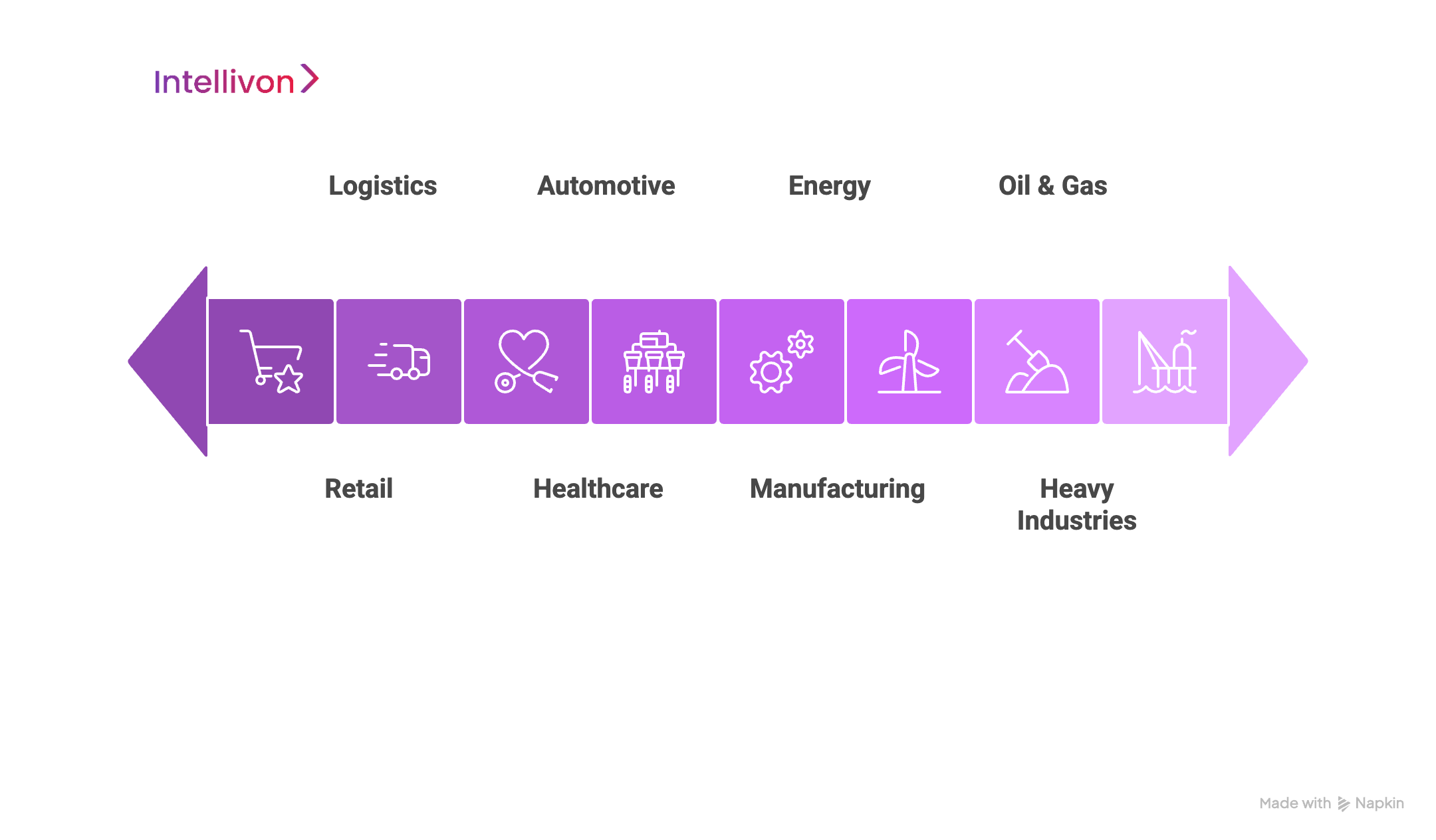

Industry-Specific Applications of Predictive Maintenance Using Edge AI

Enterprises across sectors are embracing predictive maintenance powered by Edge AI to mitigate risk, improve uptime, and reduce maintenance costs. This approach enables real-time decision-making directly at the equipment level, helping detect faults early and take action before they escalate into costly disruptions. Below is a breakdown of how key industries are applying this technology to their unique operational needs.

1. Healthcare

1. MRI and CT Scanner Monitoring

Edge AI monitors magnetic field stability, cooling mechanisms, and moving components in real time. By identifying subtle performance deviations, it helps prevent failures in imaging systems that often cost millions to repair or replace.

2. HVAC and Critical Environment Systems

In operating rooms and clean manufacturing zones, Edge AI helps maintain strict environmental control by monitoring air handling systems, filters, and pressure levels, ensuring sterile conditions and regulatory compliance.

3. Medical Device Fleet Management

From infusion pumps to ventilators and dialysis machines, Edge AI tracks device usage, performance, and wear. This allows hospital systems to detect failures early and minimize device-related downtime.

Enterprise Example: Philips Healthcare has implemented AI-powered predictive maintenance across its imaging equipment, reducing downtime by 50 % and increasing productivity by 20% in hospital networks.

2. Automotive

1. Assembly Line Robotics

Robotic arms, stamping machines, and conveyor belts are monitored using Edge AI for abnormal vibration or overheating, enabling timely intervention without disrupting production.

2. Paint Shop Equipment

Spray booths, baking ovens, and painting robots are continuously evaluated for consistent performance, preventing quality issues and minimizing equipment wear.

3. Quality Control Systems

Edge AI tracks automated inspection devices, catching early signs of sensor misalignment or mechanical drift, which can compromise defect detection.

Enterprise Example: BMW uses Edge AI to collect data across more than 30 plants globally, preventing shutdowns and optimizing maintenance across the board.

3. Manufacturing

1. CNC Machine Tool Monitoring

Edge AI analyzes spindle vibration, tool wear, and thermal drift in CNC machines, ensuring cutting accuracy and scheduling tool changes before faults occur.

2. Industrial Pump Systems

Bearing health, seal integrity, and fluid flow are continuously assessed, allowing teams to intervene before performance drops or damage sets in.

3. Compressor and HVAC Systems

Edge-based analytics track compressor cycles and HVAC load variations to predict mechanical failure and reduce energy waste.

Enterprise Example: Siemens has applied predictive maintenance AI across its turbines and factory infrastructure, reducing unplanned downtime by 30% and improving asset efficiency.

4. Retail

1. Refrigeration Systems

Edge AI continuously monitors temperature, compressor cycles, and door seal performance in freezers and coolers. This helps prevent product spoilage, reduce energy consumption, and maintain regulatory standards for food safety.

2. Escalator and Elevator Maintenance

High-traffic retail environments rely on the uninterrupted operation of elevators and escalators. Edge AI tracks motor function, vibration patterns, and brake performance to predict mechanical issues before failures impact customers.

3. POS and Self-Checkout Systems

Hardware health of checkout terminals is monitored in real time, allowing retail operations to prevent unexpected outages that lead to customer dissatisfaction or revenue loss.

Enterprise Example: Walmart uses edge sensors and smart monitoring systems to ensure food safety, reduce spoilage, and support sustainability goals in refrigeration systems.

5. Energy

1. Wind Turbine Gearbox Monitoring

Edge AI processes vibration signals, oil particulate analysis, and rotational speed metrics to detect early signs of gearbox wear. This prevents catastrophic damage in remote or offshore wind farms.

2. Solar Panel Performance

Inverter status, temperature fluctuations, and output degradation are monitored locally to ensure optimal performance across large solar fields and reduce unnecessary technician dispatches.

3. Grid Infrastructure

Transformer health, line load, and switchgear performance are tracked using edge-based models to predict failures before outages occur, supporting grid stability and maintenance planning.

Enterprise Example: General Electric uses Edge AI to monitor both wind turbine operations and jet engines. These systems have helped reduce maintenance costs and prevent mid-operation failures.

6. Heavy Industries

1. Excavator and Heavy Machinery Monitoring

Edge AI evaluates hydraulic pressure, engine load, and track or tire wear on heavy-duty machines used in mining, construction, and large-scale industrial work.

2. Conveyor Belt Systems

Predictive algorithms detect motor stress, bearing wear, and belt misalignment in high-capacity transport systems, avoiding interruptions in continuous operations like mining or raw material handling.

3. Crusher and Processing Equipment

Jaw crushers, ball mills, and separation units are monitored for vibration changes and mechanical imbalance to identify stress points before they lead to breakdowns.

Enterprise Example: Caterpillar has implemented Edge AI across its machinery fleet, enabling customers to reduce unexpected downtime by 40% and extend equipment lifespan by 15%.

7. Logistics

1. Fleet Vehicle Maintenance

Edge AI collects engine diagnostics, brake system data, and tire pressure readings in real time across commercial vehicle fleets, allowing companies to schedule maintenance without disrupting delivery timelines.

2. Warehouse Automation

Sorting systems, conveyor networks, and robotic pickers are monitored for wear, misalignment, or overheating, helping to avoid delays in fulfillment and distribution centers.

3. Port Equipment Monitoring

Edge AI tracks performance metrics from cranes, container handlers, and terminal tractors to ensure smooth and safe cargo movement at ports.

Enterprise Example: UPS uses Edge AI within its ORION logistics platform to monitor over 100,000 delivery vehicles, saving $300 million annually in maintenance costs and improving fleet reliability.

8. Oil and Gas

1. Pump and Compressor Stations

Edge systems monitor flow rates, valve integrity, and compressor dynamics in pipelines to prevent leaks, explosions, or environmental violations.

2. Refinery Equipment

Distillation columns, heat exchangers, and catalytic cracking units are evaluated in real time for thermal anomalies or pressure build-up that could indicate risk of failure.

3. Drilling Operations

Edge AI tracks mud pumps, downhole tools, and blowout preventers to ensure safe and uninterrupted drilling activity, especially in offshore or remote rigs.

Enterprise Example: Shell has integrated predictive maintenance with Edge AI across its global operations. The company reports a 30% reduction in maintenance costs and has avoided equipment failures that could have led to multi-million-dollar losses and regulatory fines.

By eliminating delays, lowering bandwidth usage, and tailoring insights to each machine’s behavior, Edge AI is redefining what’s possible for modern maintenance strategies.

Industry Benefits of Predictive Maintenance with Edge AI

Here are some industry-wise benefits for enterprises that adopt predictive maintenance with Edge AI:

1. Manufacturing

1. Real-time Anomaly Detection

Edge AI analyzes vibration, temperature, and acoustic signals directly on industrial machines to identify early warning signs of failure in CNC tools, pumps, compressors, and HVAC units.

2. Reduced Latency and Bandwidth Usage

Local data processing eliminates the need to stream high-volume sensor data to the cloud, allowing faster response times and optimized network performance.

3. Extended Equipment Lifespan

Maintenance is performed only when conditions warrant it, reducing unnecessary interventions and extending the usable life of high-value equipment.

2. Energy

1. Continuous, Offline Monitoring

Edge AI supports uninterrupted equipment monitoring in wind farms, solar installations, and grid infrastructure, even in locations with limited connectivity.

2. Reduction in Catastrophic Failures

Predictive alerts trigger timely interventions on critical assets like gearboxes and transformers, preventing unexpected outages and minimizing repair costs.

3. Data Privacy and Compliance

Operational data remains onsite, ensuring regulatory compliance and safeguarding grid-related information from external exposure.

4. Transportation and Logistics

1. Fleet Health Monitoring

Edge AI processes telematics data onboard vehicles, enabling predictive insights into engine health, brake conditions, and overall vehicle performance.

2. Operational Cost Savings

Minimized breakdowns and optimized servicing reduce maintenance spend and improve vehicle uptime across delivery and logistics fleets.

3. Real-Time Decision Support

Edge inference capabilities enable immediate actions during routing adjustments or equipment issues, especially in time-critical delivery scenarios.

5. Healthcare

1. Uptime for Critical Equipment

Edge AI monitors high-stakes medical devices such as MRI scanners and ventilators, allowing healthcare teams to identify performance issues before failures occur.

2. Sterile Environment Assurance

Edge-enabled HVAC monitoring ensures that air quality and environmental controls remain within safe parameters in surgical and pharmaceutical settings.

3. On-Site Data Security

All patient and equipment data is processed locally, supporting compliance with data protection regulations and institutional security policies

6. Heavy Industries and Mining

1. Durability in Harsh Conditions

Edge systems built for rugged environments provide reliable monitoring of machinery in mining sites and industrial zones with extreme temperatures and vibrations.

2. Downtime Reduction in Remote Operations

Even without network connectivity, Edge AI identifies early signs of wear or failure in crushers, conveyors, and hydraulic systems to ensure timely repairs.

3. Improved Safety Standards

Predictive alerts reduce the risk of equipment malfunctions that could endanger personnel or interrupt high-risk operations.

7. Retail

1. Energy-Efficient Refrigeration

By monitoring freezers and refrigeration units, Edge AI helps detect operational inefficiencies that increase energy consumption.

2. Prevention of Product Loss

Early alerts on equipment faults prevent food spoilage and inventory damage, resulting in substantial cost savings.

3. Smooth Customer Experience

Predictive maintenance of elevators, escalators, and checkout systems minimizes interruptions that affect customer flow and satisfaction.

Key Cross-Industry Benefits

1. Instant, Local Processing

Faster decision-making and issue detection are enabled by real-time processing at the device level, critical for operations where every second counts.

2. Lower Bandwidth and Transmission Costs

Edge devices send only essential summaries or anomaly alerts to the cloud, significantly reducing data transfer volumes and related costs.

3. On-Device Learning and Adaptability

Edge systems adapt to evolving asset behavior through localized model retraining, maintaining accuracy without relying on constant cloud updates.

4. Enhanced Data Privacy

Sensitive operational data remains within the enterprise network, supporting internal governance and compliance with data security standards.

5. Scalable Across Distributed Environments

Edge AI hardware is built to scale across diverse assets and remote locations, offering flexibility and continuity for enterprises with decentralized operations.

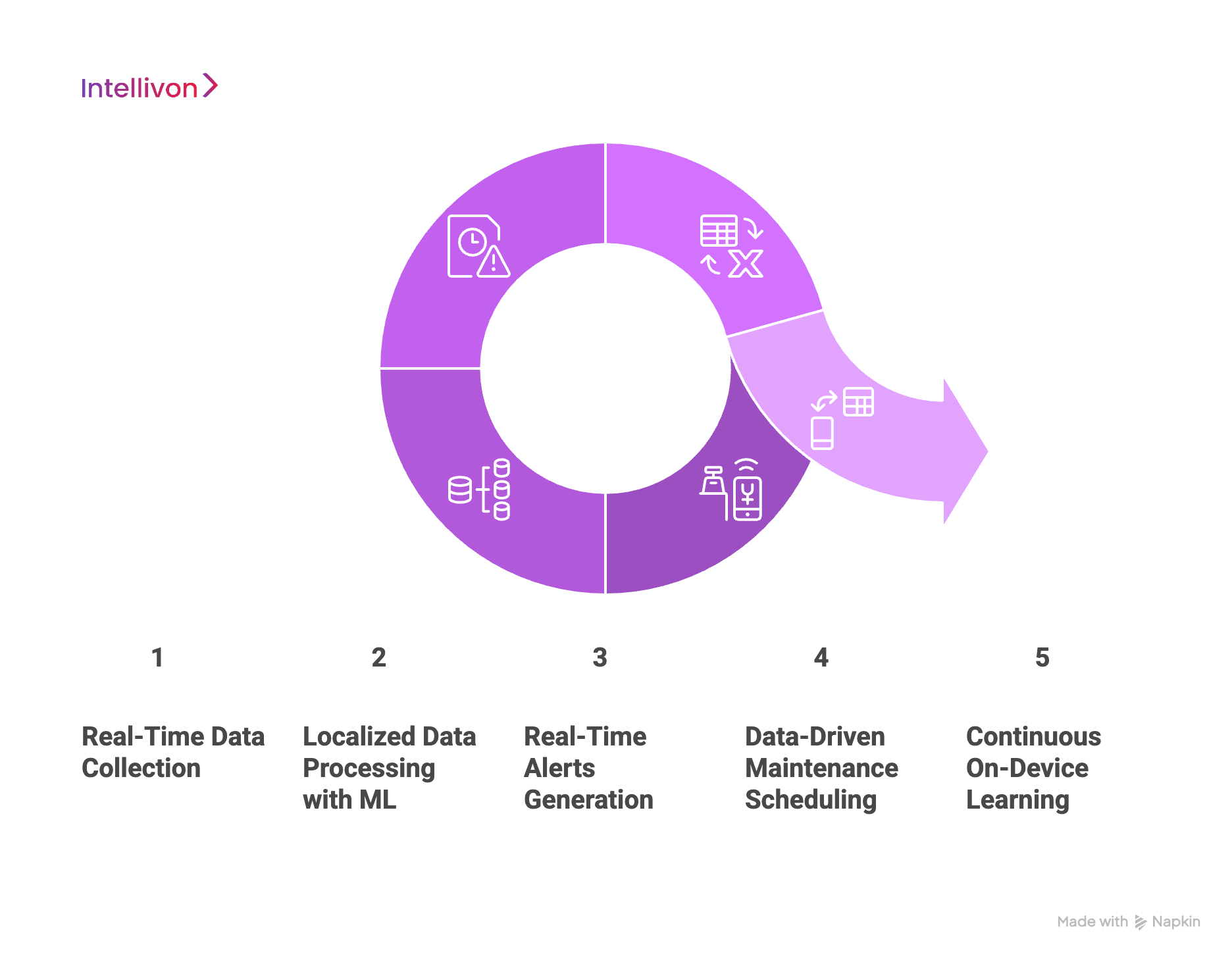

Process Edge AI Follows to Enable Smarter Predictive Maintenance

Predictive maintenance with Edge AI redefines how enterprises monitor, manage, and maintain their critical equipment. By bringing intelligence directly to the source of data, Edge AI enables faster fault detection, localized decision-making, and minimal reliance on cloud infrastructure. Here is a step-by-step look at how this process works in practice.

1. Real-Time Data Collection

The process begins with smart sensors embedded in machines such as motors, pumps, CNC tools, and HVAC systems. These sensors capture continuous streams of operational and environmental data. Key parameters include temperature, vibration frequency, pressure, sound intensity, and rotational speed. This rich dataset forms the basis for understanding machine health and identifying deviations from normal behavior.

2. Localized Data Processing with ML

Rather than routing all data to the cloud for analysis, Edge AI performs inference directly at or near the machine. Pre-trained machine learning models evaluate sensor inputs in real time, detect unusual patterns, and identify threshold breaches specific to the asset. By processing data locally, the system reduces latency and delivers actionable insights immediately, even in locations with limited connectivity. Intellivon’s expert AI/ML engineering ensures this step is carried out smoothly.

3. Real-Time Alerts Generation

When the Edge AI system detects early signs of failure, it generates instant alerts. These notifications are routed to maintenance teams via dashboards, mobile apps, or existing asset management platforms. As a result, teams can respond before issues escalate, avoiding unplanned shutdowns or equipment loss.

4. Data-Driven Maintenance Scheduling

Beyond alerting, the system also recommends optimized maintenance schedules. Using contextual information about the asset’s condition and operating environment, Edge AI helps teams determine the most effective time for intervention. This reduces unnecessary preventative maintenance and allows technicians to focus on high-priority issues, improving resource efficiency and operational planning.

5. Continuous On-Device Learning

The predictive maintenance system evolves over time. Through federated and incremental learning methods, Edge AI models continually update themselves based on new data collected from each machine. This creates a feedback loop where the system becomes more accurate and adaptive, producing diagnostics that reflect the real-world usage patterns of individual assets.

Key components of an Edge AI Predictive Maintenance Solution

To build a reliable predictive maintenance system powered by Edge AI, enterprises must combine intelligent hardware, advanced algorithms, and seamless integration. Below are the core components that enable real-time monitoring, accurate failure prediction, and actionable insights at scale.

Sensors and Data Collection

1. Types of Sensors Used

Industrial machinery is instrumented with various IoT sensors, including temperature, vibration, acoustic, pressure, and humidity sensors. Each sensor captures a specific aspect of machine health, enabling early detection of abnormalities.

2. Importance of Data Diversity

Predictive accuracy improves significantly when models can learn from both historical performance data and real-time sensor readings. Combining data streams ensures more context-aware and robust predictions.

3. Data Infrastructure and Connectivity

A stable and secure data pipeline is essential. Edge devices must support reliable communication protocols and storage systems, especially in environments with intermittent or limited network access.

AI Models and Algorithms

1. ML and DL Applications

Edge AI platforms utilize trained models for anomaly detection and failure prediction. These models identify deviations from expected behavior using supervised or unsupervised learning methods.

2. Training and Validation of AI Models

Models must be trained on asset-specific data and validated against real-world operational scenarios to ensure reliability across different environments and workloads.

3. Importance of Continuous Model Refinement

As equipment behavior changes over time, AI models must evolve. Edge-based retraining and federated learning techniques help adapt algorithms while maintaining data privacy and minimizing retraining costs.

Integration and Actionable Insights

1. Connecting with Existing Systems

Integration with CMMS, ERP, and SCADA platforms allows predictive insights to feed directly into existing maintenance workflows without disrupting operations.

2. Automated Alerts and Notifications

Edge AI systems trigger alerts when they detect anomalies, sending actionable notifications to technicians via mobile apps, dashboards, or integrated control systems.

3. User Interface and Reporting Dashboards

Custom dashboards provide real-time visibility into asset health, risk scoring, and recommended maintenance schedules. These interfaces ensure that insights are understandable and immediately usable by both operations and maintenance teams.

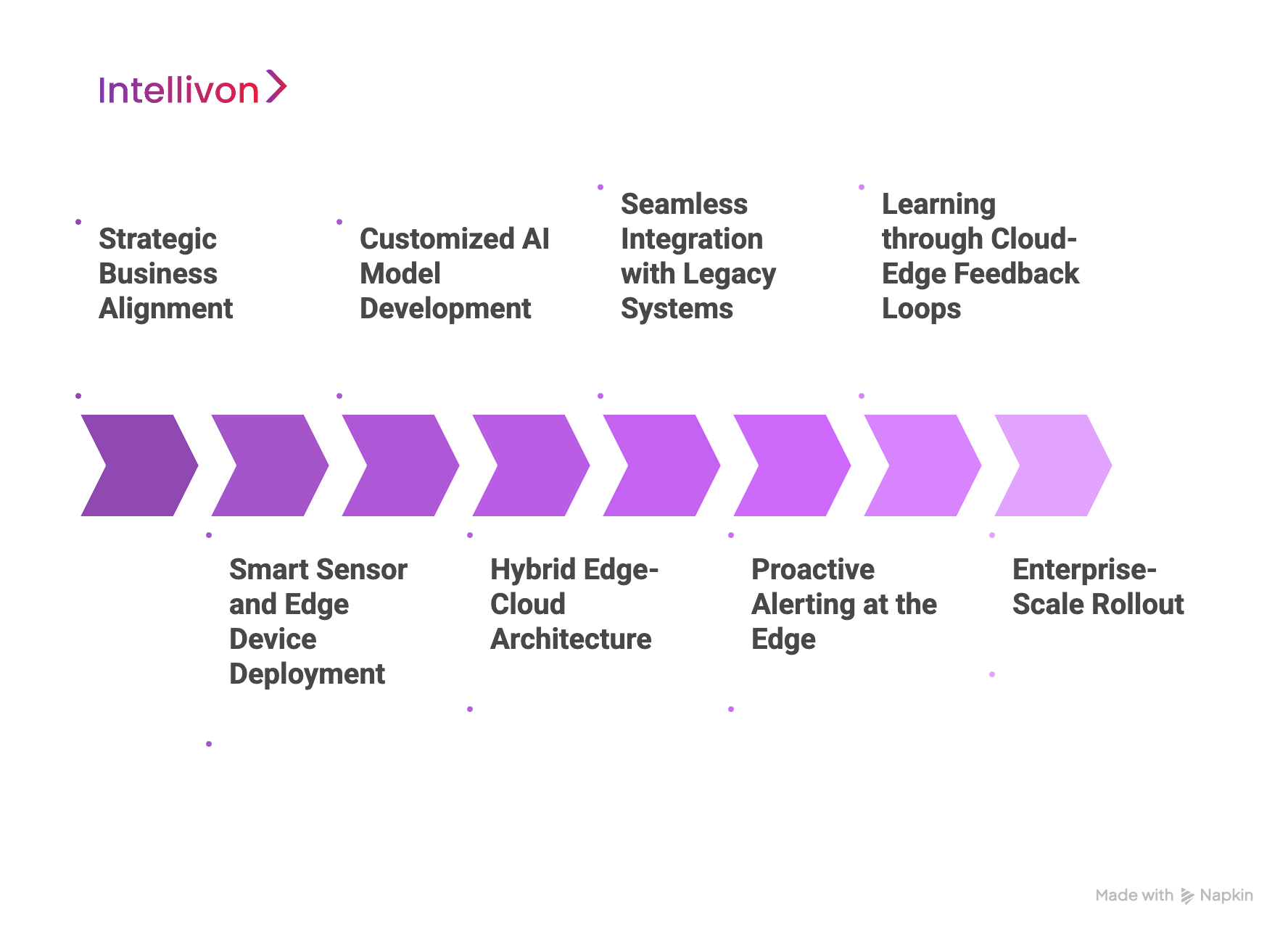

How We Implement Predictive Maintenance With Edge AI for Enterprises

At Intellivon, we take a strategic and scalable approach to deploying predictive maintenance solutions powered by Edge AI. Our framework is designed specifically for large enterprises operating complex asset environments. It bridges real-time edge intelligence with cloud capabilities, while fully integrating with existing legacy systems. Here is how we implement predictive maintenance end-to-end.

1. Strategic Business Alignment

We start by aligning predictive maintenance goals with the enterprise’s operational and financial KPIs. Through close collaboration with stakeholders, we identify whether the priority is reducing downtime, cutting maintenance costs, or extending asset lifespan.

A data-driven asset criticality assessment is then conducted to pinpoint the most impactful equipment, ensuring that deployment begins where return on investment is highest.

2. Smart Sensor and Edge Device Deployment

We equip critical assets with purpose-built IoT sensors that capture essential operational signals, including vibration, temperature, acoustics, and fluid pressure.

AI-capable edge devices are installed on-site to process this data locally, reducing the dependency on cloud infrastructure. This enables faster fault detection and ensures continuity even in environments with limited connectivity.

3. Customized AI Model Development

Using both historical and live operational data, our data science team builds machine learning models tailored to the specific failure modes and conditions of your equipment.

These models are then compressed and optimized for execution on edge devices, balancing predictive accuracy with the computational constraints of on-site hardware.

4. Hybrid Edge-Cloud Architecture

Our architecture leverages a hybrid model, distributing intelligence across both the edge and cloud layers:

Edge devices handle real-time inference and autonomous decision-making at the asset level, ensuring low latency and immediate action without external dependencies. The cloud layer performs centralized analytics, stores historical data, and supports high-volume model training. It provides enterprise-wide oversight and enables scalable updates across distributed systems. This hybrid design allows enterprises to benefit from both localized responsiveness and centralized intelligence.

5. Seamless Integration with Legacy Systems

A core strength of our approach is the ability to integrate predictive maintenance insights into your existing enterprise AI infrastructure.

Whether your organization relies on CMMS, ERP, or SCADA systems, Intellivon enables seamless connectivity through secure APIs and custom middleware solutions. This ensures uninterrupted maintenance workflows while enhancing system capabilities, without disrupting prior IT investments.

6. Proactive Alerting at the Edge

Edge AI continuously monitors incoming sensor data, identifying anomalies and failure patterns instantly. When issues are detected, the system generates real-time alerts and sends them to maintenance teams through integrated dashboards and communication tools.

Work orders can be automatically created within your enterprise systems, allowing for immediate prioritization and resolution.

7. Learning through Cloud-Edge Feedback Loops

Our systems don’t remain static. Each maintenance event and new data point contributes to refining the model over time.

Through federated and incremental learning techniques, updated models are trained in the cloud and then pushed to edge devices. This ensures that the predictive system becomes smarter with every cycle, adapting to changing equipment conditions without requiring operational downtime.

8. Enterprise-Scale Rollout

Once the initial implementation proves successful, we expand the solution across larger asset fleets in phased deployments.

Our monitoring dashboards track key metrics such as asset uptime, maintenance cost savings, prediction accuracy, and time-to-response. Regular strategic reviews with your leadership and operations teams ensure continuous improvement and long-term scalability.

Why Intellivon’s Framework Delivers Real Enterprise Value

- Combines real-time Edge AI processing with powerful cloud-based analytics for a holistic solution

- Fully integrates with existing legacy infrastructure, ensuring frictionless adoption and minimal disruption

- Enables predictive maintenance at the machine level, reducing unplanned downtime and costly failures

- Continuously improves system intelligence through live data feedback and model retraining

- Scales reliably across distributed operations, including remote and high-risk industrial environments

With this layered and intelligent framework, Intellivon empowers enterprises to move from reactive fixes to predictive foresight, transforming maintenance into a strategic, cost-saving capability powered by Edge AI. Book a strategy call with us and let us take it from here.

Key Challenges and Solutions in Developing Predictive Maintenance with Edge AI

Developing and scaling predictive maintenance systems using Edge AI holds immense potential, but enterprises often face technical, financial, and operational challenges during implementation. Below is a structured look at these challenges, paired with proven solutions based on industry best practices and Intellivon’s enterprise experience.

1. High Initial Investment

Implementing Edge AI requires upfront investment in smart sensors, industrial edge devices, AI infrastructure, and integration services. Many enterprises hesitate to adopt these systems due to budget constraints or fear of operational disruption during the transition phase.

Our Solution: Strategic Financial Planning and Modular Rollouts

Intellivon helps enterprises develop ROI-driven deployment roadmaps, beginning with targeted pilot projects. This phased approach demonstrates early wins, builds internal support, and secures incremental funding for broader rollout, minimizing risk and easing change management.

2. Inconsistent Data Quality

Predictive maintenance relies on continuous streams of high-quality sensor data. Incomplete, noisy, or misaligned data can lead to unreliable predictions, false alarms, or missed failures, undermining stakeholder confidence in the system.

Our Solution: Robust Data Management and Edge-Level Preprocessing

We deploy real-time anomaly detection and data validation protocols directly on edge devices. Combined with calibrated sensor configurations and AI-based cleansing pipelines, this ensures only reliable, contextual data powers your predictive models, improving accuracy from the ground up.

3. Legacy Enterprise Systems Integration

Many large enterprises operate on legacy systems like ERP, CMMS, and SCADA, which are often siloed, proprietary, and incompatible with new AI-driven platforms. This creates friction during rollout and risks fragmented operations.

Our Solution: Seamless Legacy Integration Through Secure APIs

Intellivon delivers middleware that connects Edge AI systems with existing enterprise software through industry-standard APIs. Our integration layer preserves existing workflows while enriching them with predictive intelligence, eliminating the need to overhaul infrastructure.

4. Limited Connectivity in Remote Environments

Field operations in mining, energy, and industrial manufacturing often face intermittent connectivity. Cloud-only systems become unreliable in such environments, while bandwidth limitations restrict large-scale data transmission.

Our Solution: Resilient Hybrid Edge-Cloud Architecture

We design edge-first systems that perform critical inference and decision-making locally, with selective synchronization to the cloud for centralized oversight and model updates. This approach ensures reliability, even in low-connectivity zones, while optimizing bandwidth usage.

5. Complexity in AI Model Development

Building accurate, efficient, and adaptable AI models for resource-constrained edge devices is a technical challenge. Enterprises often lack the in-house capability to manage training, compression, and continuous adaptation.

Our Solution: Customized AI Models with Continuous Learning

Our data scientists create models tailored to your specific assets and operations. We support federated and incremental learning frameworks, allowing edge models to evolve over time based on live sensor feedback, without requiring constant retraining or manual updates.

6. Enterprise Skills Gap

AI implementation requires expertise in industrial operations, machine learning, and IoT architecture. Resistance to change and limited cross-functional collaboration can stall or derail initiatives.

Our Solution: Workforce Enablement and Change Management Programs

Intellivon offers in-depth training programs and leadership workshops to equip operations, IT, and maintenance teams with the skills they need. We also guide enterprise-wide stakeholder alignment, ensuring cultural buy-in and a shared vision for long-term adoption.

7. Data Privacy Concerns

As edge devices and industrial networks grow, so does the attack surface. Without a comprehensive strategy, sensitive data and mission-critical systems may be exposed to cybersecurity risks.

Our Solution: Multi-Layered Industrial Cybersecurity Framework

Our solution stack includes end-to-end encryption, device-level authentication, secure firmware updates, and compliance with data protection regulations. We continuously monitor for threats and anomalies, ensuring your predictive maintenance infrastructure remains protected and compliant.

By addressing each of these challenges through a structured and integrated framework, Intellivon helps enterprises unlock the true value of predictive maintenance with Edge AI, enabling smarter operations, higher uptime, and measurable ROI at scale.

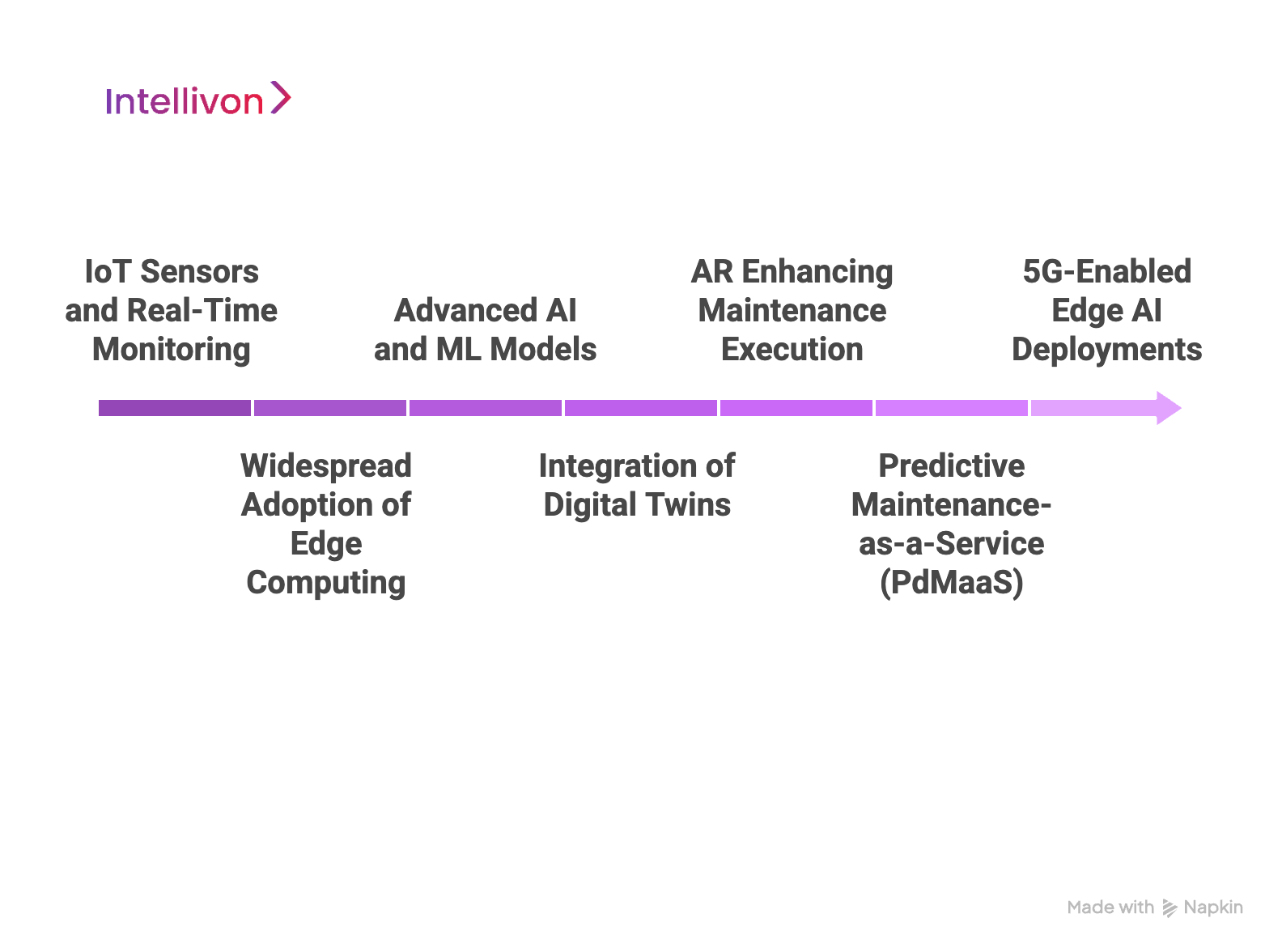

Future Trends in Predictive Maintenance with Edge AI for Enterprises

As industrial operations become increasingly connected and data-driven, predictive maintenance powered by Edge AI is evolving rapidly. Here are the top trends shaping the future of this technology, and what they mean for enterprises aiming to stay competitive.

1. IoT Sensors and Real-Time Monitoring

Enterprises are deploying a growing number of IoT sensors to monitor diverse parameters such as vibration, pressure, acoustics, humidity, and temperature. This dense sensor network enables real-time visibility into machine conditions and supports earlier, more accurate detection of anomalies.

2. Widespread Adoption of Edge Computing

As more enterprise data is processed at the edge, Edge AI will become essential for delivering fast, autonomous insights. Local analytics reduce latency, eliminate delays from cloud dependency, and enable instant responses to potential failures.

3. Advanced AI and ML Models

AI algorithms are becoming increasingly sophisticated, capable of performing complex tasks such as remaining useful life (RUL) estimation, root cause analysis, and failure classification. These models will increasingly run natively on edge devices, delivering faster and more context-aware decisions.

4. Integration of Digital Twins

Digital twins will combine live sensor data with AI-driven simulations to model asset behavior in real time. This allows teams to test failure scenarios virtually, optimize maintenance strategies, and reduce equipment downtime by up to 30%.

5. AR Enhancing Maintenance Execution

AR tools will overlay predictive maintenance data in real time, guiding field technicians through diagnostics and repairs. These solutions improve task accuracy, reduce error rates, and enable remote collaboration with experts, especially valuable in high-risk or remote environments.

6. Predictive Maintenance-as-a-Service (PdMaaS)

Enterprises are moving toward subscription-based PdMaaS platforms, which reduce capital expenditure and simplify deployment. These solutions provide access to the latest sensor technology, AI models, and analytics dashboards without the burden of in-house development.

7. 5G-Enabled Edge AI Deployments

The spread of 5G will improve bandwidth and reduce network latency, making it possible to run high-frequency analytics at the edge. This enables seamless coordination between edge devices and cloud platforms, especially critical for distributed industrial operations.

What These Trends Mean for Enterprises

Enterprises that proactively adopt these innovations will gain a competitive edge by transitioning from reactive maintenance to predictive, autonomous systems that:

- Minimize unexpected downtime and increase equipment lifespan

- Reduce cloud dependency while improving real-time responsiveness

- Strengthen data security across IoT-connected assets

- Boost technician productivity using AR and automation

- Scale predictive maintenance efficiently through PdMaaS platforms

These trends point to a future where predictive maintenance is not just a technical upgrade, but a strategic differentiator, one that enhances operational resilience and enables smarter, faster decision-making across the enterprise.

Conclusion

Enterprises struggling with latency, fragmented asset visibility, data overload, and false alarms can now shift to a truly predictive maintenance strategy with Edge AI.

Intellivon’s tailored solutions deliver real-time insights, reduced downtime, and smarter decision-making across your entire asset ecosystem.

Ready to Transform Maintenance with Predictive Edge AI?

With over 11 years of enterprise AI expertise and more than 500 successful deployments worldwide, Intellivon is your trusted partner in building scalable, intelligent predictive maintenance systems that deliver measurable operational impact. From real-time anomaly detection to seamless legacy integration, we help global enterprises move from reactive maintenance to proactive, data-driven strategies.

What Sets Intellivon Apart?

- Tailored Predictive Frameworks: We design, develop, and deploy Edge AI-powered solutions that align with your asset ecosystem and business KPIs, ensuring maximum uptime and ROI.

- Edge-Cloud Synergy: Our hybrid architecture combines instant edge-level insights with centralized cloud analytics, enabling fast decisions and continuous model evolution.

- Legacy System Integration: We integrate predictive maintenance into your existing ERP, CMMS, and SCADA systems without disrupting workflows.

- Human-Centric Rollout: From pilot deployment to enterprise-wide scale-up, our change management experts ensure smooth adoption and cross-team collaboration.

- Continuous Improvement: We provide ongoing AI model refinement, real-time performance monitoring, and strategic optimization tailored to your business growth.

Contact Intellivon for a Full Predictive Maintenance Readiness Assessment. Our experts will deliver:

- A deep-dive audit of your current maintenance processes and infrastructure

- Edge AI compatibility and integration planning

- A use-case-driven deployment roadmap with ROI projections

- Industry benchmarking and scalability blueprint

Book your free strategy call with an Intellivon expert today and start building a predictive, resilient, and intelligent maintenance future.

FAQ’s

Q1. What is the difference between traditional and Edge AI predictive maintenance?

Traditional predictive maintenance relies on cloud-based analytics, which introduces latency and depends on constant connectivity. Edge AI processes data locally at the equipment level, enabling real-time insights, faster failure detection, and autonomous decision-making, even in low-connectivity environments.

Q2. How can Edge AI reduce unplanned downtime in industrial environments?

Edge AI continuously monitors sensor data and detects anomalies in real time, enabling maintenance teams to intervene before equipment fails. This reduces unexpected breakdowns, increases uptime, and helps schedule repairs more efficiently based on actual asset conditions.

Q3. Can Edge AI predictive maintenance integrate with existing ERP and CMMS systems?

Yes, Edge AI platforms can be integrated with legacy systems like ERP, CMMS, and SCADA using APIs and middleware. This ensures seamless data flow, automates maintenance workflows, and protects prior IT investments while enhancing operational intelligence.

Q4. What types of industries benefit most from Edge AI-based predictive maintenance?

Industries with high-value, distributed, or mission-critical assets, such as manufacturing, energy, healthcare, logistics, and mining, see the greatest ROI. Edge AI enables localized, real-time monitoring even in remote or harsh environments, where cloud-only solutions may fall short.

Q5. Is Edge AI predictive maintenance scalable across large enterprise operations?

Yes, Edge AI systems are designed for enterprise-scale deployments. They support distributed asset fleets, adapt to evolving equipment behavior through federated learning, and synchronize with cloud platforms for centralized oversight, making them ideal for global industrial operations.