In retail, classic demand forecasting models simply cannot keep up with a growing economy shaped by inflation, unpredictable supply chains, viral social media trends, and shifting customer expectations. As a result, retail enterprises are facing costly overstocks, frequent stockouts, and eroding profit margins.

AI-powered demand prediction platforms are transforming these problems into sustainable and scalable solutions. Instead of relying only on historical data, these systems combine machine learning, deep learning, and external signals to predict demand with unprecedented accuracy. These systems quickly adapt to changing customer behaviours and buying trends, giving retailers the ability to act on real-time insights, run real-life scenarios, and align inventory with true customer demand.

We’ve spent years building these systems for leading retailers, turning chaotic inventory guesswork into precise forecasting that prevents stockouts and slashes waste. In this blog, we share our process by explaining why these platforms have become essential, how we approach development to match real business needs, and what it takes to build something that genuinely scales with your enterprise and delivers measurable gains.

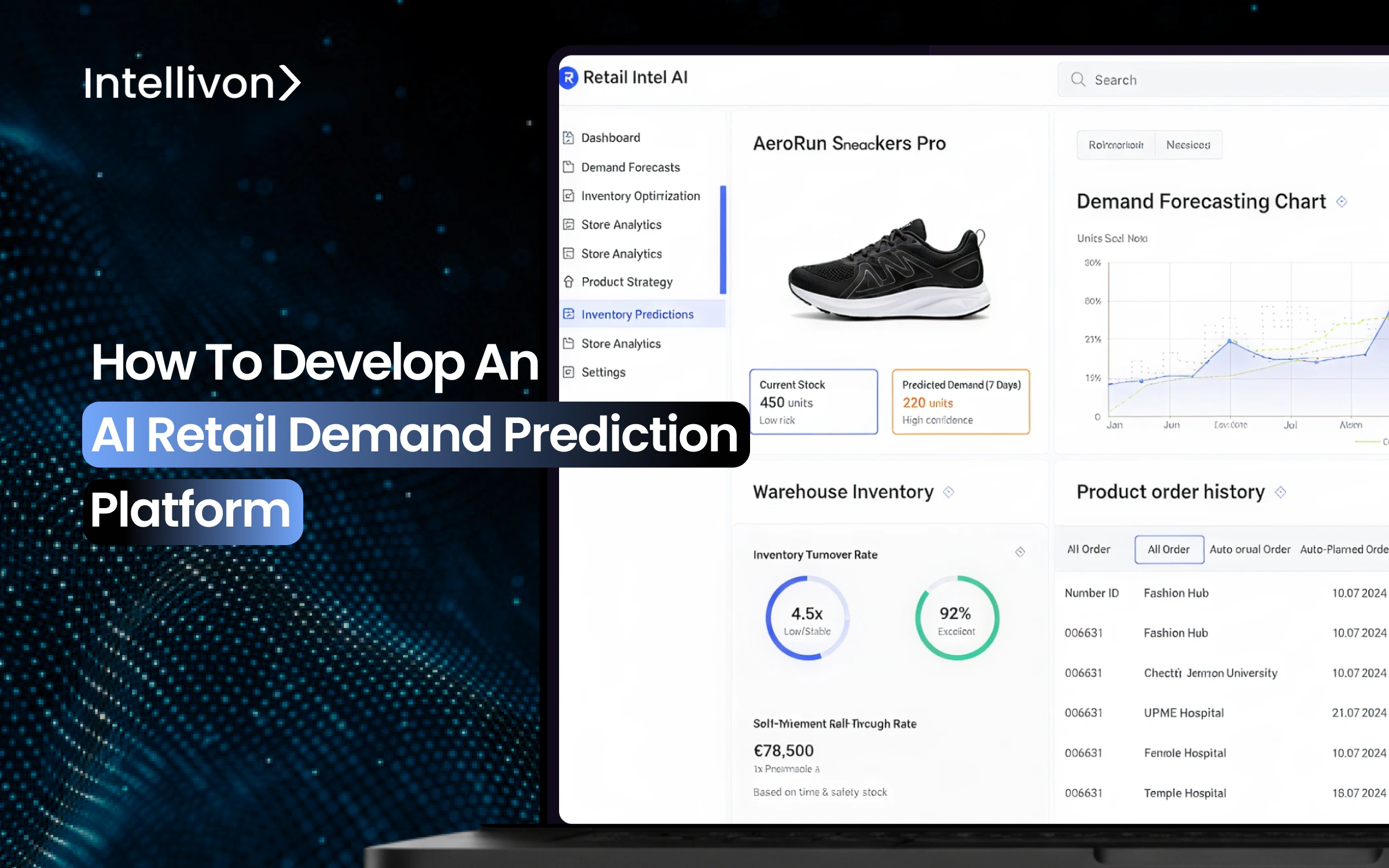

What is an AI Retail Demand Prediction Platform?

An AI retail demand prediction platform is a decision engine that helps retailers understand what products will sell, where they will sell, and when demand will peak, with a high level of accuracy.

Unlike legacy models that lean heavily on historical sales data, these platforms ingest real-time signals such as promotions, competitor pricing, weather, social media trends, and even economic shifts. This allows forecasts to adapt dynamically to fast-changing retail conditions.

For global retailers, the platform’s value lies in resilience and not merely as a forecasting tool. When supply chains are disrupted, consumer behavior shifts overnight, or a viral trend suddenly drives demand for a single product line, an AI-powered platform enables a rapid response. That means fewer stockouts, less capital tied up in excess inventory, and more consistent availability of the products customers actually want.

In practice, the platform becomes the foundation of modern retail planning, helping executives align supply, merchandising, pricing, and logistics with the realities of a volatile market.

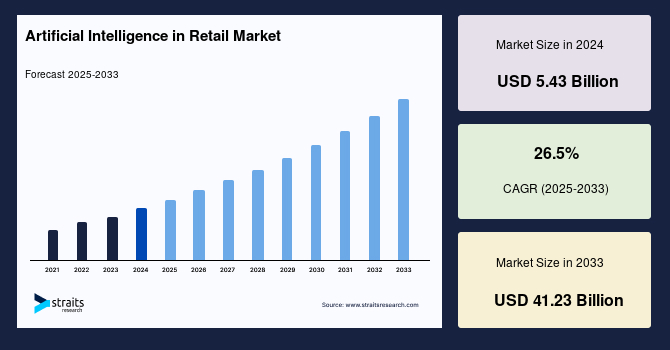

Key Takeaways of the AI Retail Market

The global AI in retail market was worth USD 5.4 billion in 2024 and is expected to rise sharply, reaching USD 41.2 billion by 2033. From 2025 to 2033, it is forecast to expand at a 26.5% annual growth rate, reflecting strong demand for AI-driven retail solutions.

- Retailers using AI demand prediction report 20–50% better forecast accuracy than traditional models.

- These gains cut stockouts, reduce excess inventory by 15–30%, and improve on-shelf availability, boosting sales.

- The retail supply chain AI market is expected to grow at 35%+ CAGR through 2030.

- Automated forecasting linked to ERP and inventory systems enables real-time, multi-location demand insights.

- Over 60% of Fortune 500 retailers already leverage AI-driven demand forecasting at scale.

- Advanced models address data silos, shifting consumer behavior, and seasonal or promotional volatility.

- Investment is rising through venture funding, partnerships, and acquisitions, driving rapid platform innovation.

- Leading platforms emphasize scalability, easy integration, and explainable predictions for adoption across retail teams.

- Adoption is strongest in North America, Europe, and the Asia-Pacific region, with emerging markets rapidly catching up.

- AI forecasting delivers a sustainable competitive advantage, making this the right moment to invest in enterprise-grade platforms like Intellivon’s.

How an AI Retail Demand Prediction Platform Works

Building accurate demand forecasts with AI relies on creating a pipeline that transforms raw retail data into actionable predictions, which feed directly into supply chain, merchandising, and pricing systems. The process typically follows five stages:

1. Data Ingestion

The process begins with data collection. Internal systems provide the backbone, such as sales, POS, ERP records, promotions, inventory levels, and supply chain logs.

To sharpen accuracy, the platform also pulls in external signals such as weather forecasts, holiday calendars, competitor pricing, economic indicators, and even social media trends.

Once gathered, the data is cleaned, deduplicated, and organized at the SKU, store, and channel level to create a reliable base for forecasting.

2. Feature Engineering

Raw numbers only become useful when translated into predictive signals. Here, the system identifies patterns like seasonality and demand trends, measures price elasticity, and calculates promotional uplift.

It also detects product affinities. For example, a spike in coffee sales often boosts sales of mugs or filters. External influences such as weather or regional events are factored in, making forecasts more realistic and adaptable to real-world conditions.

3. Modeling Layer

This is where intelligence takes shape. Multiple modeling techniques work in tandem to cover different aspects of demand.

- Time-series models such as Prophet or ARIMA capture historical patterns.

- Deep learning models like LSTMs and Transformers recognize more complex, long-term behaviors across categories.

- Causal machine learning then isolates the specific effects of promotions or price changes.

By blending these approaches into an ensemble, the platform delivers accurate forecasts across short-, mid-, and long-term horizons.

4. Prediction Output

The forecasts generated are not broad estimates but highly granular insights. Retailers receive SKU-by-store-by-day predictions that guide replenishment decisions with precision. Similarly, scenario planning allows teams to test questions like, “What happens if we run a 20% promotion in Germany?”

Confidence intervals are also included, so decision makers understand not only the prediction but the level of certainty behind it.

5. Integration and Action

The final step is what makes the platform transformative. Forecasts are fed directly into ERP, WMS, and supply chain systems, where they can trigger operational actions automatically.

This includes reorder alerts when inventory dips, markdown recommendations for slow-moving products, or pricing adjustments to optimize margins.

The platform also balances stock across online and offline channels, keeping availability consistent no matter how customers choose to shop.

AI retail demand prediction platform turns predictions into immediate business actions. That connection between insight and execution is what makes it so powerful for retailers competing a global scale.

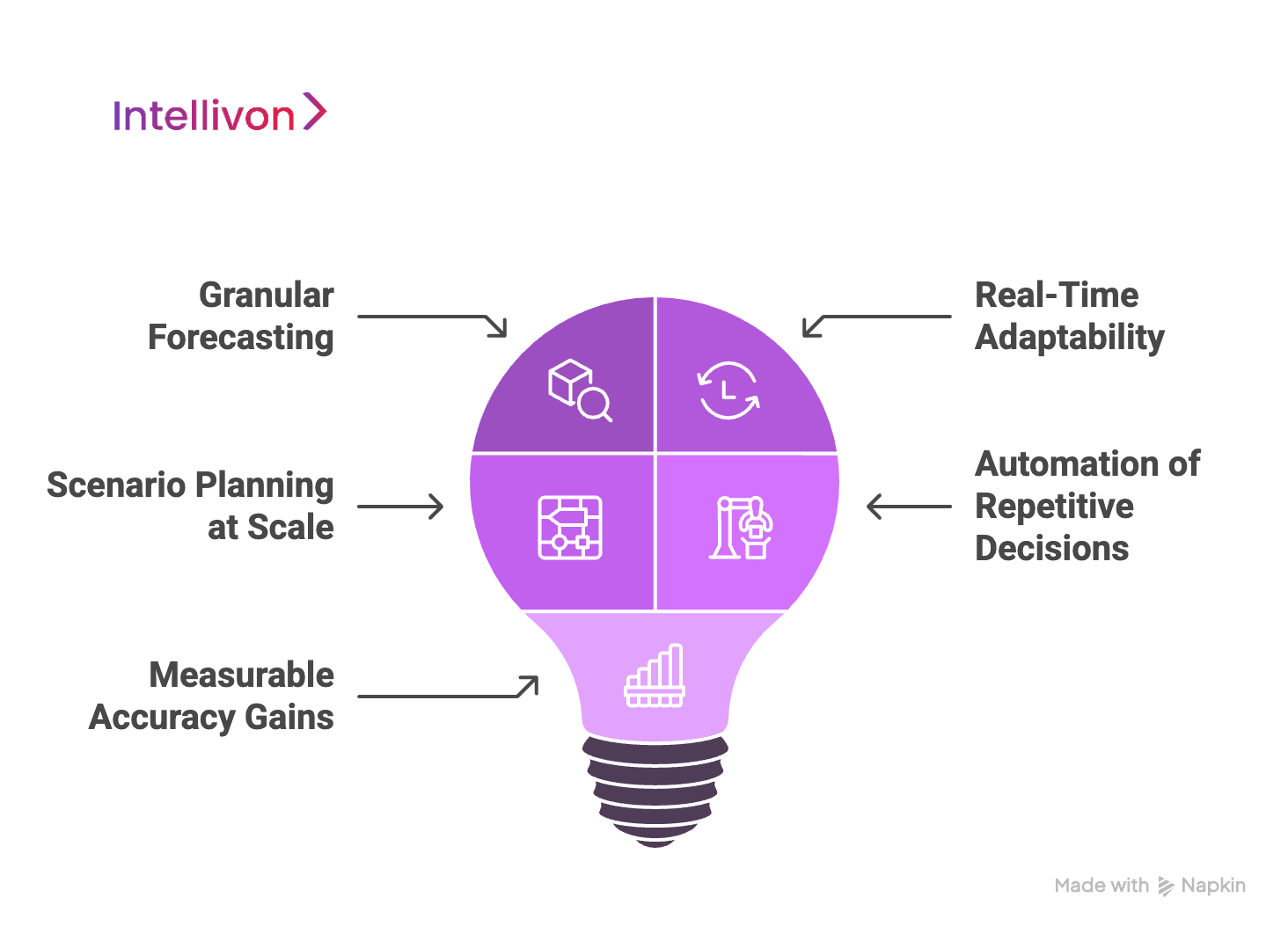

How AI Enhances Retail Demand Prediction Platforms

Traditional demand planning systems often struggle with complexity, wherein they look backward at historical sales and apply basic statistical models. AI-enhanced platforms, on the other hand, bring a level of granularity, adaptability, and automation that reshapes how retailers plan and respond to demand.

1. Granular Forecasting

Instead of broad category-level predictions, AI platforms operate at the SKU × Store × Channel level. This means a forecast isn’t “how much soda will sell this quarter,” but “how many units of a specific brand and size will sell in each store, online marketplace, or region.”

2. Real-Time Adaptability

Consumer demand changes quickly, like weather shifts, viral social media posts, or sudden inflationary pressures, can flip expectations overnight. AI platforms adjust forecasts in near real time, helping retailers react before shelves empty or warehouses overfill.

3. Scenario Planning at Scale

AI allows planners to simulate “what-if” scenarios. For example: “What happens if we launch a promotion in Spain? Or how would a 10% price cut affect sales in North America?” This enables proactive decision-making instead of reactive firefighting.

4. Automation of Repetitive Decisions

Instead of relying on manual input, the system can automatically trigger stock replenishment, price adjustments, or markdown strategies. This reduces human bottlenecks and ensures that responses happen at the speed of the market.

5. Measurable Accuracy Gains

Studies and retail benchmarks show that AI-driven forecasts can reduce error rates by 20–50% compared to legacy models. For enterprises, this translates into fewer stockouts, less capital tied up in excess inventory, and a measurable improvement in on-shelf availability.

In short, AI enhances retail demand prediction platforms by making them faster, sharper, and more resilient. The outcome is a planning system that continuously learns, adapts, and acts in step with consumer behavior.

Use Cases of AI Retail Demand Prediction Platforms

Leading retailers are already using AI-powered retail demand prediction platforms to solve challenges that legacy planning systems couldn’t handle. Here are some of the most impactful applications.

1. Stockout and Overstock Prevention

Inventory imbalances cost retailers billions every year, where empty shelves mean lost sales, while overstock ties up working capital. Walmart leverages AI-driven forecasting to predict demand spikes during holidays and regional events. The result is fewer stockouts on high-demand items and leaner inventory levels on slower-moving products.

2. Promo Impact Forecasting

Promotions boost sales but can also erode margins if poorly forecasted. Carrefour applies AI to model how promotions will drive uplift across different regions. This helps them optimize budgets, choose the right products to promote, and avoid unnecessary markdowns once campaigns end.

3. Dynamic Pricing

Demand is fluid, and so are prices. Amazon is a benchmark example, where its ML-driven pricing engine updates millions of product prices daily, balancing customer demand with margin protection. AI ensures price shifts are strategic rather than reactive.

4. New Product Launch Forecasting

Forecasting demand for new products is notoriously difficult because there’s little or no historical data. Nike uses AI to analyze social media buzz, influencer trends, and search data to predict demand for new sneaker drops. This allows them to adjust production and distribution before launch, avoiding both shortages and excess stock.

5. Omnichannel Demand Forecasting

Consumers shop across online and offline channels, but stock often isn’t aligned between them. Tesco applies AI forecasts that cover both digital and physical stores, ensuring consistency. This prevents the situation where an item is overstocked in one channel and unavailable in another.

6. Weather-Sensitive Demand

Weather can dramatically shift purchasing behavior. Target integrates weather data into its forecasting models, predicting spikes in umbrellas and raincoats during storms, or ice cream sales during heatwaves. This ensures local stores are stocked with the right products at the right time.

7. Supply Chain Disruption Response

Fast-fashion and global retail depend on fragile supply chains. Zara uses AI to adapt production and distribution when shipping delays or raw material shortages occur. By forecasting demand with alternative sourcing plans, Zara maintains agility while competitors face shortages.

These examples show that AI retail demand prediction is grounded in making operations more resilient, responsive, and profitable. From global giants like Amazon and Walmart to fast movers like Zara, retailers are proving that predictive intelligence can be the difference between keeping up and leading the market.

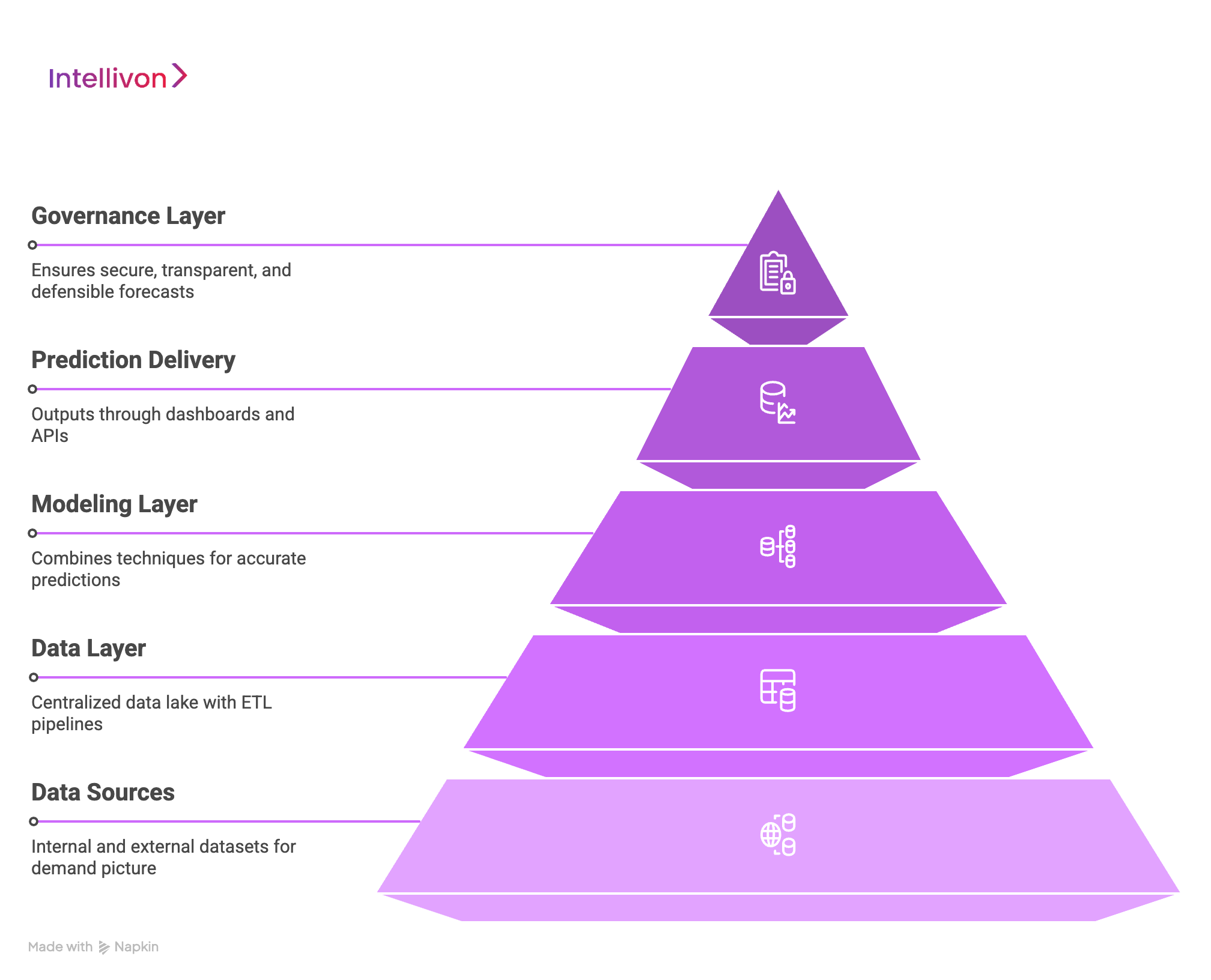

Architecture of an AI Retail Demand Prediction Platform

A retail demand prediction platform is a full-stack system that brings together data, intelligence, and business workflows into a single, seamless engine. At enterprise scale, the architecture typically unfolds across five key layers.

1. Data Sources

Everything starts with the right inputs. The platform combines both internal and external datasets to capture the full demand picture:

- Internal sources: POS and ERP sales, inventory levels, promotions, e-commerce transactions, and supply chain records.

- External signals: Competitor pricing, weather forecasts, holiday calendars, social media sentiment, and broader economic indicators.

This blend ensures forecasts reflect not only what has happened, but what is likely to influence consumer demand next.

2. Data Layer

Once collected, all data flows into a centralized data lake (AWS S3, Azure Data Lake, or similar). From there, ETL pipelines clean, standardize, and unify information down to the SKU, store, and channel level.

Feature engineering adds predictive power, like building signals such as seasonality, cross-product affinities, and price elasticity. By this stage, raw transactions have been transformed into structured, meaningful predictors.

3. Modeling Layer

The modeling layer is the intelligence core. Here, multiple techniques are combined to maximize accuracy:

- Time-series models like ARIMA or Prophet for historical trends.

- Deep learning models such as LSTMs and Transformers for complex, long-range patterns.

- Causal ML models to isolate the true impact of promotions, price shifts, or external events.

An ensemble approach blends these models, with AutoML ensuring they adapt as shopper behavior evolves over time.

4. Prediction Delivery Layer

Forecasts only matter if they reach the right decision makers. Outputs are delivered through:

- Dashboards (Power BI, Tableau) that give planners a clear view of SKU-level forecasts, confidence intervals, and promo scenarios.

- APIs that feed predictions directly into ERP, WMS, or merchandising platforms, turning forecasts into operational decisions.

- Automated alerts that flag when stock needs replenishment, markdowns are advisable, or a promotion will drive unexpected demand.

5. Governance Layer

At enterprise scale, trust is everything. The governance layer ensures forecasts are secure, transparent, and defensible:

- Data security with end-to-end encryption and role-based access.

- Model monitoring that detects drift and keeps forecasts accurate over time.

- Compliance alignment with GDPR, data residency, and privacy rules across jurisdictions.

- Explainability reports that make it clear why forecasts were generated, giving executives confidence when presenting outcomes to boards or regulators.

This layered architecture makes an AI retail demand prediction platform into an accurate decision engine that retailers can rely on to align supply, pricing, and merchandising with real-time market realities.

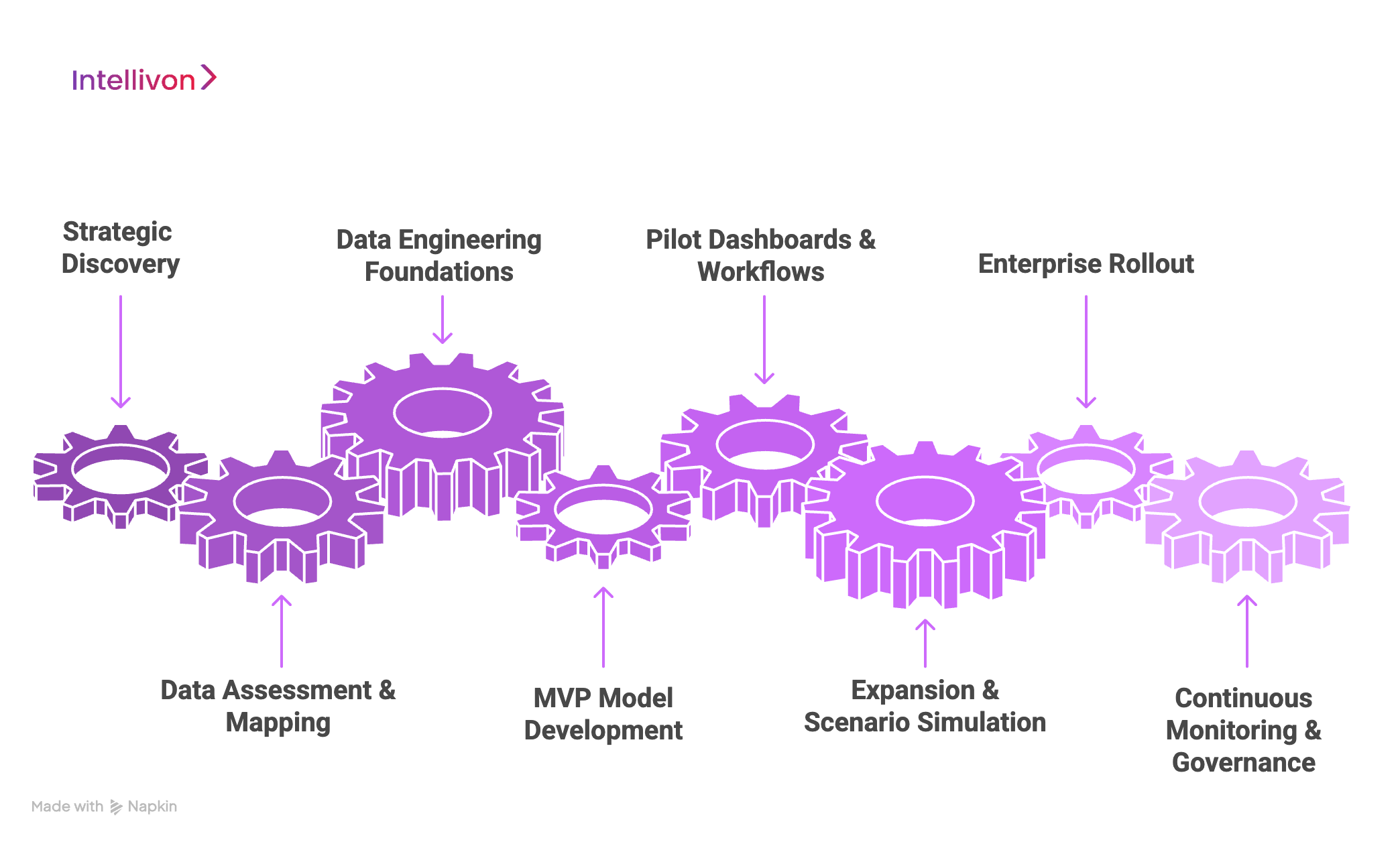

How We Develop an AI Retail Demand Prediction Platform

At Intellivon, we design demand prediction systems that fit the reality of modern retail, which includes fragmented data, volatile demand, thin margins, and global operations. Our process ensures platforms actively improve supply chain resilience, merchandising accuracy, and revenue outcomes.

Step 1: Strategic Discovery

We begin by aligning with leadership teams on demand planning pain points. For a grocery chain, this may mean reducing holiday stockouts in fresh produce. For a fashion retailer, it could be preventing excess inventory on seasonal collections.

Similarly, for an omnichannel brand, it often involves synchronizing forecasts across online and offline channels. By pinpointing these goals, we ensure every technical decision supports a business outcome that matters.

Step 2: Data Assessment & Mapping

Retailers often juggle POS feeds from thousands of stores, ERP purchase orders, e-commerce logs, and distributor data, all formatted differently. We catalog each source and assess its reliability.

For example, POS data may be delayed by 24 hours, or promo tags may be inconsistent across regions. We also evaluate external data, which is increasingly vital in retail forecasting. This step creates a data readiness map that highlights what’s usable and what needs remediation.

Step 3: Data Engineering Foundations

With sources identified, we build a retail-specific data lake that organizes information at the SKU, store, and channel level. This includes cleansing product hierarchies, aligning promotion calendars, and mapping supplier lead times.

Feature engineering turns this into predictive signals, like how a 10% discount historically lifted sales in a given region, or how weather shifts affected ice cream vs. hot beverage sales.

Step 4: MVP Model Development

We start with a minimum viable forecast model targeting a few categories with high business impact. For a supermarket, this could be staples like bread, milk, and household goods.

At the same time, for an apparel retailer, it may focus on fast-moving seasonal lines. Models combine time-series forecasting for baseline demand, deep learning for long-range patterns, and causal ML for isolating promo effects. This allows the MVP to not just predict, but explain why demand will shift.

Step 5: Pilot Dashboards & Workflows

Forecasts need to be actionable, and for that, we build PowerBI or Tableau dashboards showing daily/weekly SKU-level forecasts, promo lift expectations, and confidence ranges.

For example, planners can see that a promo in Germany will likely increase sales of a detergent brand by 18–22%. We also pilot ERP and WMS integrations, so replenishment planners can test forecasts in their actual ordering systems before full rollout.

Step 6: Expansion & Scenario Simulation

After validating accuracy in pilots, we scale to more categories, geographies, and channels. The next layer is building scenario simulators. Retailers can now ask:

- What if we run a 30% off promo in France during Easter?

- How will a viral TikTok trend affect sneaker demand in the US?

- What happens if a shipment from Vietnam is delayed by three weeks?

This moves forecasting from being backward-looking to forward-planning, arming executives with options before decisions are made.

Step 7: Enterprise Rollout

The platform is rolled out across all SKUs and regions, integrated with core systems. Forecasts feed directly into ERP purchase orders, merchandising systems, and markdown engines. Automated triggers reorder stock, rebalance inventory between online/offline channels, or adjust prices in real time.

For example, if stock runs low in-store but remains high in the warehouse, the system can recommend a fast transfer instead of new orders.

Step 8: Continuous Monitoring & Governance

Retail demand is dynamic, since models degrade as trends shift. We set up drift monitoring dashboards that alert planners when accuracy drops below thresholds, triggering retraining.

We also build in compliance, keeping in mind that GDPR governs customer-level data, while regional residency laws ensure EU data remains within EU servers. Quarterly reviews ensure the platform stays aligned with evolving business goals, whether that’s responding to inflation, supply disruptions, or sustainability targets.

This process ensures retailers don’t just deploy another system, but build a living demand prediction engine that keeps pace with consumer behavior and market volatility.

Cost of Developing An AI Retail Demand Prediction Platform

At Intellivon, we understand that global retailers need demand prediction systems that are accurate, resilient, and cost-effective. That’s why our pricing model is structured to be flexible and aligned with your retail priorities, and not a one-size-fits-all package.

If costs risk exceeding budget, we work with your team to streamline scope while safeguarding the core value of stock accuracy, promotional efficiency, and supply chain resilience.

Estimated Phase-Wise Cost Breakdown

| Phase | Description | Estimated Cost Range (USD) |

| Discovery & Data Audit | Map POS, ERP, e-commerce, and supply chain feeds. Assess data quality, identify gaps, and set forecasting KPIs. | $8,000 – $12,000 |

| Data Engineering & Integration | Build ETL pipelines, unify SKUs across systems, and set up a retail data lake. Integrate external signals (weather, social, competitor pricing). | $10,000 – $16,000 |

| Model Development | Develop hybrid forecasting models (time-series + ML + deep learning). Pilot MVP with 2–3 product categories. | $12,000 – $20,000 |

| Scenario Simulator | Deploy what-if engines to test promotions, price changes, supply delays, and regional rollouts. | $8,000 – $14,000 |

| Dashboards & API Integration | Build forecasting dashboards in PowerBI/Tableau. Connect predictions to ERP, WMS, and merchandising systems via secure APIs. | $10,000 – $16,000 |

| Governance & Monitoring | Set up model drift detection, explainability reports, audit logs, and compliance checks (GDPR, regional data residency). | $6,000 – $10,000 |

| Training & Change Management | Conduct workshops for planners and merchandisers. Support adoption with human-in-the-loop workflows and trust-building. | $4,000 – $8,000 |

Total Initial Investment Range: $58,000 – $96,000

Ongoing Optimization (Annual): $8,000 – $15,000

Factors That Influence Cost

The final investment depends on several variables:

- Data Landscape: Number of POS, ERP, and e-commerce systems, and complexity of SKU alignment.

- Model Sophistication: Whether forecasts are short-term only or span long-term, causal, and promotional effects.

- External Signal Integration: Adding social, weather, or competitor data feeds increases accuracy but requires more engineering.

- Deployment Model: Cloud-native (AWS, Azure, GCP), hybrid, or on-premises, depending on compliance needs.

- Customization Depth: Tailored dashboards and scenario planners vs. modular, pre-configured interfaces.

- Advanced Features: Promo uplift simulators, omnichannel forecasting, and dynamic pricing modules.

Request a tailored quote from Intellivon’s AI engineers today. We’ll design a retail demand prediction platform that fits your budget, reduces inventory risk, and scales with your growth strategy.

Top Retailers Already Using AI Demand Prediction

AI demand prediction is no longer a future trend — it’s already embedded in the operations of the world’s largest retailers. Their adoption highlights how these platforms directly impact supply chain agility, pricing, and customer experience.

1. Walmart

Walmart has long been at the forefront of retail innovation, and AI-driven demand forecasting now plays a central role in its supply chain. During holiday seasons and peak shopping periods, the platform anticipates demand surges down to specific categories and regions.

This enables stores to stay stocked on essentials while reducing overstocks on slower-moving items. The scale of Walmart’s network means even a small improvement in accuracy translates into massive savings and improved customer satisfaction.

2. Amazon

Dynamic pricing has become one of Amazon’s most powerful competitive levers, and AI sits behind it. The company updates millions of product prices daily, continuously balancing supply, demand, and margin targets.

Beyond pricing, Amazon’s demand forecasting feeds into its global fulfillment centers, ensuring fast-moving items are always close to customers. This integrated use of AI means fewer delivery delays and sharper alignment between demand signals and supply chain execution.

3. Carrefour

As one of Europe’s largest retailers, Carrefour applies AI to improve promotional planning. Instead of relying on historical uplift assumptions, its forecasting models evaluate how different promotions perform across regions and product categories.

The result is more efficient use of promotional budgets and fewer markdowns after campaigns end. For a retailer operating across diverse markets, this adaptability is crucial to maintaining margins while staying competitive.

4. Tesco

Tesco’s strength lies in managing both online and offline demand. Its AI demand prediction platform aligns forecasts across e-commerce and physical stores, minimizing discrepancies in stock availability.

For example, if a product trends online, forecasts ensure local stores are also stocked to meet heightened demand. This synchronization helps Tesco serve customers seamlessly across channels, preventing missed sales while reducing waste.

5. Nike

For brands like Nike, the challenge is predicting the popularity of new product launches. Nike incorporates social media and trend signals into its forecasting models to gauge demand for upcoming sneaker drops. By adjusting production and distribution before launch, Nike reduces the risk of shortages or unsold inventory.

This creates smoother launches and strengthens the connection between brand excitement and product availability.

These examples demonstrate that AI retail demand prediction is not a theoretical investment. It is a proven capability driving measurable improvements in efficiency, agility, and customer experience at the world’s largest retailers.

Overcoming AI Retail Demand Prediction Platform Deployment Challenges

While deploying an AI retail demand prediction platform, the technology may be proven, but organizational realities create barriers that need careful handling. At Intellivon, we design platforms with these obstacles in mind, embedding solutions that make adoption smoother and outcomes stronger.

1. Breaking Down Data Silos

Retailers often operate with a patchwork of systems that rarely “speak” the same language. SKUs may be labeled differently, promotions may not be tagged consistently, and e-commerce data may lag behind in integration. The result is fragmented visibility and inconsistent inputs, which weaken forecast accuracy from the start.

Intellivon Solution: We design unified data lakes and ETL pipelines that consolidate feeds across all these systems. SKUs are harmonized, duplicates are cleaned, and promotions are standardized so that the forecasting models work with reliable inputs. The outcome is a single source of truth where demand signals are clear, consistent, and ready to drive accurate predictions.

2. Managing Model Drift

Demand models are never static. A forecast built on last year’s consumer behavior may miss shifts caused by inflation, supply shortages, or unexpected global events. For example, pandemic-era models often failed once in-store shopping patterns rebounded. Left unchecked, model drift undermines confidence and forces planners back into manual workarounds.

Intellivon Solution: Our platforms continuously monitor model accuracy against actuals. Drift detection flags when forecasts start deviating beyond accepted thresholds, and automated retraining keeps models aligned with current realities. Planners receive transparent notifications when a model is adjusted, helping them understand that accuracy is actively managed.

3. Integrating External Signals

External signals like weather, competitor pricing, and social trends can add immense forecasting value, but they are also noisy. A spike in social mentions might reflect hype, not actual purchase intent. Weather changes may affect some categories dramatically (ice cream, umbrellas) but leave others untouched. Without careful filtering, external data can mislead forecasts and create false confidence.

Intellivon Solution: We use causal machine learning to separate correlation from causation. For example, our models can determine whether a sales bump was truly driven by a TikTok trend or if it coincided with a promotion. By isolating the real drivers of demand, we ensure external signals improve accuracy instead of distorting it.

4. Building Planner Trust

One of the most overlooked challenges is cultural, and not technical. Demand planners and merchandisers often rely on years of experience, gut feel, and spreadsheets. Introducing AI forecasts without transparency can make teams feel sidelined or skeptical. If planners can’t see how a forecast was generated, they may revert to their own methods, leaving the platform underutilized.

Intellivon Solution: We design explainable dashboards that show why a forecast was made, which signals influenced it, and how confident the model is. A planner reviewing a holiday forecast, for example, will see that the prediction was based on last year’s uplift, weather expectations, and competitor pricing. Human-in-the-loop workflows allow planners to adjust forecasts or approve them before execution, ensuring AI complements expertise rather than replacing it.

5. Compliance and Privacy Risks

Global retailers operate across regions with strict compliance obligations. Customer-level or transaction data must be managed under GDPR in Europe, CCPA in California, and similar regulations elsewhere. Mishandling data not only exposes companies to fines but also damages consumer trust. Cross-border operations add complexity. Data collected in France, for example, may not legally be transferred to US servers.

Intellivon Solution: We build compliance into the architecture. Data is encrypted at rest and in transit, with regional residency controls to keep EU data within EU borders. Personally identifiable information can be anonymized, while access controls limit who sees sensitive data. This ensures the forecasting system meets legal requirements and can withstand audits without costly retrofits.

By addressing the structural, cultural, and regulatory hurdles that typically derail AI projects, Intellivon ensures demand prediction platforms move beyond pilot stages into enterprise-wide impact.

Conclusion

Retail has always been a balancing act, by keeping shelves stocked without tying up cash in excess inventory, pricing competitively without destroying margins, and reacting to consumer shifts before they erode sales. Now, promotions can ripple through markets overnight, social trends can create instant demand spikes, and global supply disruptions can unravel months of planning. Traditional forecasting systems, built on historical averages, simply cannot keep pace.

AI-powered demand prediction platforms offer a new foundation. By combining real-time data, external signals, and advanced modeling, they provide forecasts that are not only more accurate but also more adaptive. Retailers that adopt them gain the ability to act with confidence, reallocating inventory before shortages occur, shaping promotions based on predicted uplift, and even pricing dynamically in response to shifting demand.

Build Your Next Retail Demand Prediction Platform With Intellivon

At Intellivon, we design enterprise-grade demand prediction platforms that are precise, resilient, and built for global retail operations. Our approach blends advanced AI modeling, real-time external signal integration, and governance-first architecture to help retailers improve accuracy without compromising compliance or trust.

Why Partner With Intellivon?

- Tailored Solutions: We align forecasting systems with your product categories, channels, and strategic goals.

- Compliance-First Design: GDPR, CCPA, and data residency rules are embedded into every build.

- Proven Retail Expertise: Our platforms support grocery, fashion, e-commerce, and omnichannel models with measurable ROI.

- Scalable Architecture: Cloud-native, API-driven design ensures seamless integration and long-term adaptability.

Book a discovery call with Intellivon today. Let’s build a demand prediction platform that reduces inventory risk, strengthens margins, and positions your enterprise to lead in the next era of retail.

FAQs

Q1. What is an AI retail demand prediction platform?

A1. It’s an enterprise system that uses AI and machine learning to forecast product demand at the SKU, store, and channel level. Unlike traditional tools, it factors in real-time signals such as promotions, weather, social trends, and competitor pricing to create adaptive, accurate forecasts.

Q2. How do retailers benefit from AI retail demand prediction?

A2. Retailers gain higher forecast accuracy, fewer stockouts, and reduced excess inventory. It improves promo planning, optimizes pricing, and ensures products are available where and when customers need them. The result is stronger margins and improved customer satisfaction.

Q3. What data is required for AI demand forecasting?

A3. Key data sources include POS and ERP sales, e-commerce transactions, promotion calendars, supply chain feeds, and distributor data. External signals such as weather, social media, competitor pricing, and macroeconomic indicators are layered in for greater accuracy.

Q4. How long does it take to implement an AI retail demand prediction platform?

A4. Most retailers see a working MVP in 8–12 weeks, covering a few core categories. Full-scale rollout across SKUs, regions, and channels typically takes 4–6 months, depending on the size of operations and integration scope.

Q4. How does AI improve forecast accuracy compared to traditional models?

A5. AI platforms reduce forecast errors by 20–50% compared to legacy systems. They achieve this by analyzing far more signals, learning from patterns faster, and adapting quickly to unexpected events such as supply chain delays or viral product demand.