It is hard to keep track of goods moving through a global supply chain. This is because when these products cross regions, data often gets scattered across systems, leaving blind spots that make it difficult for enterprises to monitor inventory, verify authenticity, or respond quickly when issues arise. A blockchain supply chain platform addresses this by creating a secure, transparent network where every movement is captured on a tamper-proof ledger. From sourcing raw materials to final delivery, stakeholders involved in the lifecycle have access to real-time updates, ensuring correct data, accurate tracking, and the removal of manual checks or siloed records.

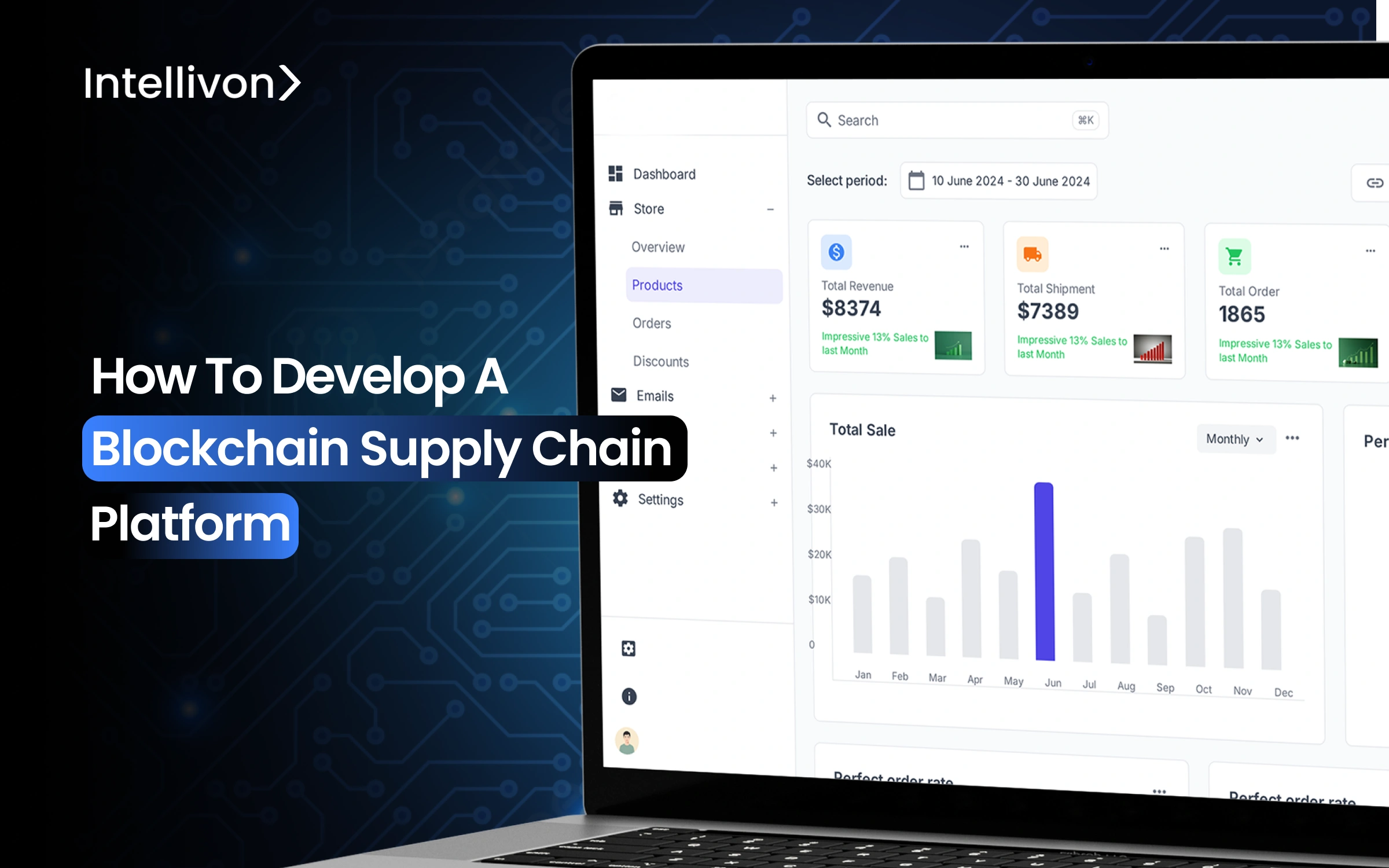

At Intellivon, we’ve built blockchain supply chain platforms for enterprises that require both high-level security and the ability to scale. By integrating blockchain with IoT sensors, ERP systems, and advanced analytics, we design networks that go beyond simply recording events, preventing fraud, accelerating recalls, and simplifying compliance. In this blog, we’ll explore what these platforms are, how they work, how we develop them from the ground up, and how leading companies are already using them to run more transparent and resilient supply chains.

What Is a Blockchain Supply Chain Platform?

At its core, a blockchain supply chain platform is the trust backbone for global logistics and trade networks. Instead of relying on fragmented databases managed by individual partners, it creates a single, distributed ledger where every transaction, from sourcing raw materials to delivering finished goods, is recorded in a tamper-proof, time-stamped format.

What sets these platforms apart is not just the technology, but the design principle of shared truth. Each participant, whether a supplier, manufacturer, logistics provider, retailer, or regulator, sees the same verified data in real time. This eliminates disputes, reduces the risk of fraud, and ensures that all parties are working from a unified version of events.

The key elements include:

- Shared ledger: A common record accessible to authorized parties.

- Transparency: All stakeholders see verifiable updates without intermediaries.

- Immutability: Once written, records cannot be altered or erased.

- Smart contracts: Automated rules that trigger actions like payments or recalls.

For enterprises, the value lies in achieving continuous visibility, audit readiness, and improved resilience in a world where supply chains are increasingly global and complex.

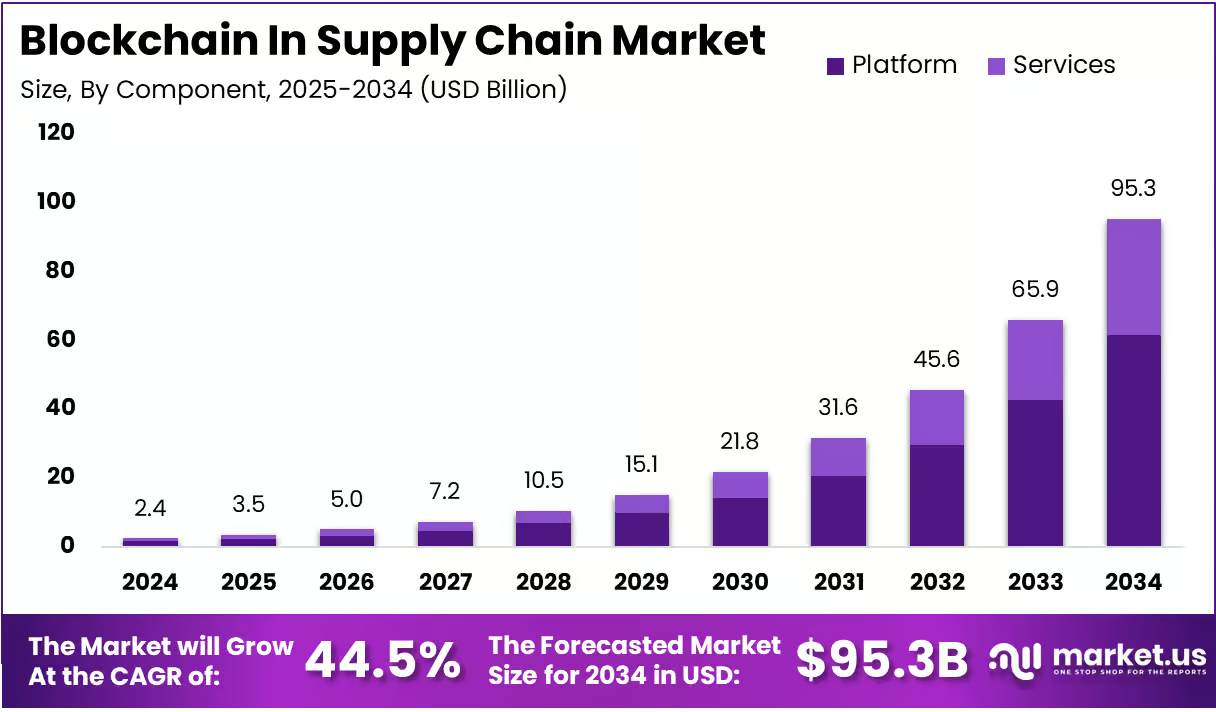

Key Takeaways of the Blockchain In the Supply Chain Market Size

The global blockchain in supply chain market is on a rapid growth trajectory. Valued at just USD 2.4 billion in 2024, it is projected to surge to USD 95.3 billion by 2034, growing at an impressive CAGR of 44.5%.

Key Results and Adoption Trends:

- Research across 150+ deployments shows that nearly 80% of organizations achieve ROI within 18–24 months, which is a strong signal that blockchain is no longer experimental, but a proven driver of enterprise transformation.

- Enterprises see an average 20–30% reduction in supply chain costs after implementation.

- Blockchain improves traceability by 75% and cuts documentation processing time by 85%.

- Fraud detection and counterfeit prevention improve by up to 92% in pharmaceuticals and luxury goods.

- Food recalls are completed up to 73% faster, reducing risk and waste.

- Walmart cut food traceability times from 7 days to 2.2 seconds, saving millions in logistics.

- Infosys reports 60% annual growth in pilots moving to production, especially among Tier 1 suppliers.

- McKinsey projects 45% efficiency gains in digital supply chains, led by pharma, retail, and automotive.

- Smart contracts reduce reconciliation costs by up to 70% by automating payments and invoice workflows.

- Global blockchain spending is expected to exceed USD 17.9 billion in 2024, with supply chain platforms driving the fastest growth.

How Do Blockchain Supply Chain Platforms Work?

A blockchain supply chain platform functions as a living system of record that captures every movement, transformation, and verification step across the product lifecycle. Instead of each partner keeping siloed data, the platform ensures that all authorized stakeholders interact with the same version of the truth, one that cannot be altered retroactively.

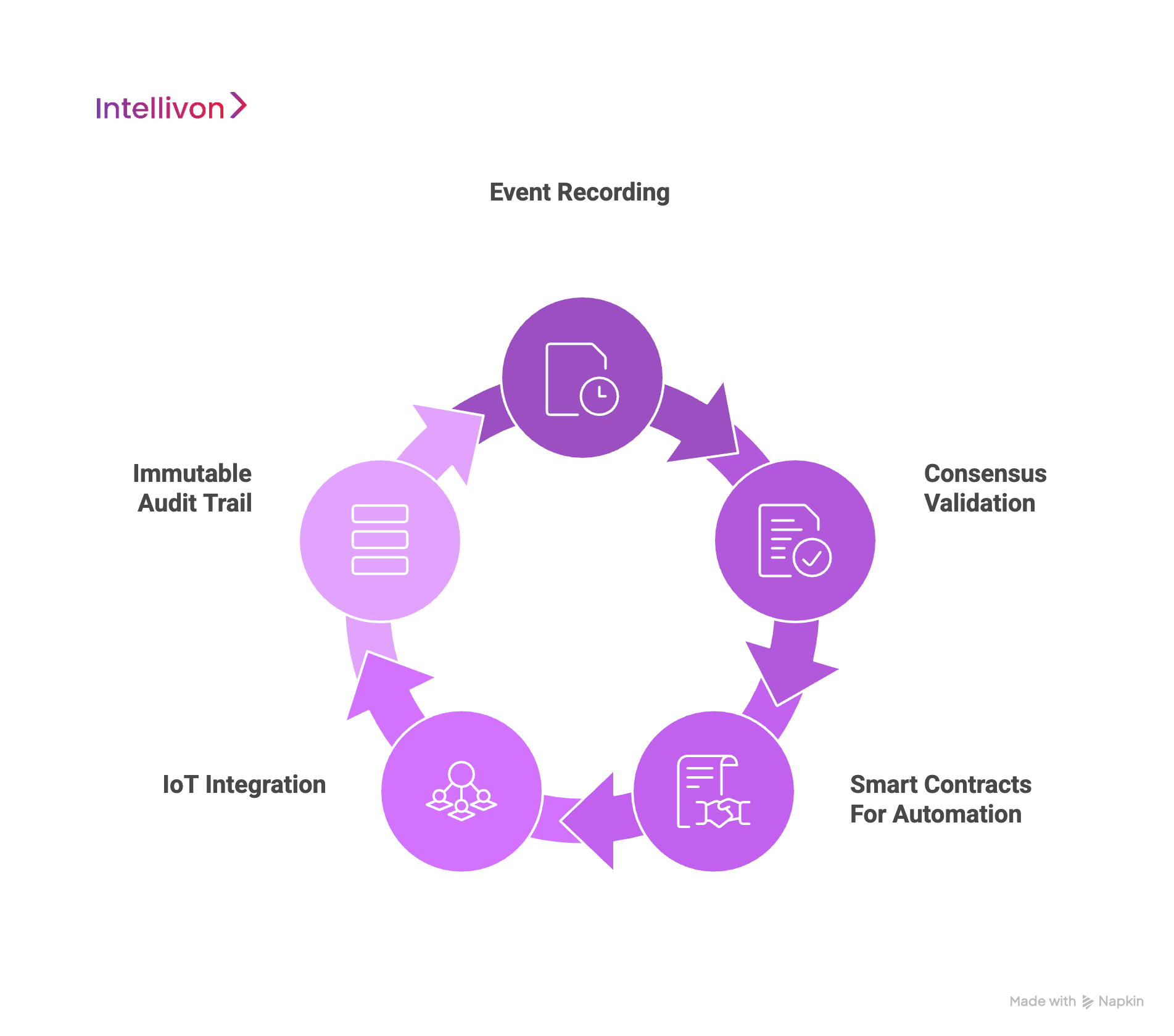

Here’s how it works step by step:

1. Event Recording

Each action in the supply chain, whether it is a batch produced, a shipment dispatched, or a quality check completed, is recorded as a blockchain transaction. These events are time-stamped and digitally signed, creating a permanent trail.

2. Consensus Validation

Transactions aren’t accepted blindly since the system validates them based on preset rules. For example, only an accredited quality lab can approve a batch, or only a licensed transporter can initiate a shipping event. This ensures trust without manual verification.

3. Smart Contracts for Automation

Smart contracts execute rules automatically. A supplier can receive payment once a delivery is confirmed, or a recall alert can trigger if a batch fails a compliance check. These contracts cut delays and remove reliance on paper trails.

4. IoT Integration

IoT devices such as RFID tags, GPS trackers, or temperature sensors feed real-world data into the platform. Blockchain anchors this telemetry immutably, enabling enterprises to prove conditions like cold-chain compliance or real-time location.

5. Immutable Audit Trail

Every event is linked in chronological order. Regulators, auditors, and business leaders can query this trail to verify provenance, check compliance, or investigate anomalies. Unlike traditional databases, nothing can be edited or deleted later.

The result is a synchronized, tamper-proof, and automated ecosystem. Instead of chasing information across dozens of partners, enterprises can see the full journey of their products in real time and with guaranteed integrity.

Use Cases of Blockchain in Supply Chains

Blockchain platforms are already reshaping how global supply chains operate. Their value lies in addressing long-standing pain points with verifiable transparency and automation. Here are some of the most practical applications:

1. Product Traceability and Provenance

Track every step of a product’s journey, from raw material origin to retail shelf, with the help of blockchain. This technology is critical in industries like food, pharmaceuticals, and luxury goods, where authenticity and safety are paramount. A blockchain ledger ensures that the data’s origin cannot be faked or erased, giving regulators and customers full confidence.

2. Counterfeit Prevention

Counterfeiters often target high-value goods such as branded electronics, medicines, and diamonds. By issuing each unit a unique digital identity recorded on blockchain, enterprises can verify authenticity instantly and block fake products from entering legitimate markets.

3. Cold Chain Monitoring

Temperature-sensitive products, such as vaccines, seafood, and dairy, rely on flawless cold chain management. IoT sensors feed real-time data into the blockchain, where deviations from required conditions are flagged immediately. This allows enterprises to intervene early and prevent costly spoilage.

4. Automated Payments via Smart Contracts

Smart contracts automate financial flows between trading partners. Through this system, a transporter can be paid automatically when delivery is confirmed on-chain, removing disputes and reducing manual reconciliation efforts.

5. Regulatory Compliance and Auditing

Whether meeting FDA’s DSCSA requirements in pharma or EU product passport rules in manufacturing, blockchain provides audit-ready records. Compliance checks are no longer a scramble, and this is because regulators can access immutable proof of every transaction.

6. Targeted Recalls

Instead of recalling entire product lines, blockchain enables precise recalls down to the affected batch or unit. This saves millions in wasted product and helps protect brand reputation while ensuring consumer safety.

7. Sustainability and ESG Validation

Consumers and regulators increasingly demand proof of ethical sourcing. Blockchain platforms log certifications (fair trade, organic, carbon footprint) and verify them against the product journey, providing transparency in sustainability claims.

Blockchain supply chain platforms are becoming the digital infrastructure enterprises need to protect trust, improve efficiency, and meet regulatory demands. By combining transparency, automation, and security, they enable leaders to build supply chains that are not only resilient but also positioned for future growth.

Must-Have Features of a Blockchain Supply Chain Platform

For a blockchain supply chain platform to truly add enterprise value, it needs more than a distributed ledger. It must deliver visibility, automation, and compliance while integrating seamlessly with the systems already running the business. Below are the features that separate a proof-of-concept from a platform that can scale across industries.

1. End-to-End Traceability

Every product, from raw material to finished unit, should carry a digital identity that follows it through the entire supply chain. Recording each transformation creates a permanent product history, so when a recall is triggered, enterprises can pull up a verifiable, tamper-proof record in seconds.

2. Chain-of-Custody Tracking

Supply chains often fail at handoff points, where goods change custody between partners. A blockchain platform eliminates that risk by logging every transfer of responsibility with a time-stamped, digitally signed event. Whether a shipment moves from a supplier to a carrier or from a distributor to a retailer, the system creates an unbroken record.

This chain-of-custody transparency prevents disputes, improves accountability, and ensures regulators can verify exactly where goods have been at any moment in time.

3. Smart Contract Automation

Manual approvals, reconciliations, and compliance checks slow supply chains down. Smart contracts allow enterprises to embed business rules directly into the platform.

For example, a supplier can be paid automatically once a delivery is scanned and verified, or a recall alert can be triggered if a quality control test fails. By automating critical processes, smart contracts reduce errors, speed up decision-making, and eliminate the need for constant manual oversight.

4. IoT and Sensor Integration

The physical world and the digital ledger must stay in sync, and that is why integration with IoT devices is essential. RFID tags, GPS trackers, and environmental sensors continuously feed data into the blockchain.

This ensures not only that a shipment has moved, but also that it has been stored and transported under the correct conditions. For temperature-sensitive goods like vaccines or seafood, this creates irrefutable evidence of cold chain compliance and gives enterprises confidence in product quality.

5. Permissioned Access and Privacy Controls

Enterprises want transparency but not at the cost of exposing sensitive data. A blockchain platform must allow fine-grained control over who sees what.

Role-based permissions and selective data sharing mean that a retailer can confirm product authenticity without seeing contract pricing, and a regulator can verify compliance without gaining access to commercial details. This balance of openness and confidentiality is what makes enterprise adoption possible.

6. Seamless Enterprise Integration

Most supply chains already run on ERP, WMS, and transport management systems that are deeply embedded in day-to-day operations. A blockchain platform should integrate with these systems through APIs and middleware rather than forcing organizations to replace them.

When designed correctly, blockchain becomes the trusted backbone that unifies data across partners, while existing tools continue to handle planning, execution, and reporting.

7. Compliance and Audit Readiness

Regulators across industries are demanding more stringent traceability, from the FDA’s DSCSA in pharma to EU product passports in manufacturing. A must-have feature of any blockchain supply chain platform is the ability to generate audit-ready reports instantly.

By structuring data around global standards such as GS1 EPCIS, enterprises ensure that they can satisfy auditors and regulators without last-minute data collection exercises.

8. Scalability and High Performance

Recording every scan and event directly on-chain can create performance bottlenecks. A well-designed platform uses a hybrid model, where high-volume data streams (like IoT telemetry) are stored off-chain, while cryptographic proofs are anchored on-chain.

This keeps the ledger lean and fast, while still guaranteeing data authenticity. Scalability is critical, where an enterprise platform must handle millions of daily events without lag or system slowdowns.

9. Exception Handling and Recall Management

Supply chains are not static, and exceptions happen every day, such as delayed shipments, damaged goods, or failed quality checks. A blockchain platform must provide tools to quickly isolate affected units or batches and take targeted action.

In the event of a recall, this means identifying exactly which products are impacted, where they are located, and who needs to be notified, all in real time. This precision prevents unnecessary waste and protects brand reputation.

10. Real-Time Analytics Dashboards

Modern blockchain platforms offer dashboards that visualize product flows, supplier performance, and compliance status in real time. By combining blockchain data with analytics, enterprises can spot inefficiencies, respond quickly to disruptions, and create strategic advantages from the information they already generate.

These features are the difference between a blockchain pilot that stalls and a platform that delivers measurable ROI. Enterprises that prioritize end-to-end traceability, automation, IoT integration, and compliance alignment will unlock real efficiency gains, while those that overlook them risk building systems that look promising on paper but fail in practice.

Architecture and Tools Behind These Platforms

At Intellivon, we’ve seen too many blockchain pilots fail because they lacked a robust, enterprise-ready architecture. Our approach is different because we have built a layered framework that ensures security, scalability, and seamless integration from the ground up.

Our Five-Layer Architecture

1. Blockchain Ledger Layer

Our platforms run on permissioned frameworks such as Hyperledger Fabric, Quorum, or Corda. These give enterprises the governance, auditability, and throughput they need, without exposing sensitive data on public chains. Every supply chain event is recorded immutably, creating a foundation of trust.

2. Data Capture Layer (IoT and Edge Devices)

We design blockchain to reflect the real world by integrating RFID, GPS, temperature sensors, and smart packaging. Our platforms are built to capture live data at the edge. Every reading is cryptographically signed and linked to a product’s digital identity, making it impossible to tamper with shipment or quality records.

3. Integration Layer (ERP, WMS, TMS Connectors)

Enterprises can’t rip out SAP, Oracle, or legacy WMS systems overnight. Our integration layer connects blockchain directly into these environments through APIs and middleware, so blockchain becomes the trust backbone without disrupting operations.

4. Off-Chain Data Stores

Intellivon’s architecture uses hybrid storage. High-volume data streams like IoT telemetry or certifications are stored off-chain in secure cloud or enterprise databases, with cryptographic hashes anchored on-chain. This design keeps the ledger lean while preserving proof of integrity.

5. Analytics and Dashboard Layer

Our platforms surface real-time intelligence, not just records. Executives and compliance teams get dashboards showing product flows, supplier performance, and recall status, all backed by blockchain proofs. This turns immutable data into actionable insights.

Tools We Deploy for Enterprises

- Frameworks: Hyperledger Fabric, Quorum, Corda.

- Standards: GS1 EPCIS for regulatory and partner interoperability.

- IoT Devices: RFID tags, GPS, temperature sensors.

- Middleware: Kafka, MuleSoft, and custom APIs for integration.

- Cloud: AWS Managed Blockchain, Azure Blockchain, IBM Blockchain.

Intellivon’s architecture is the result of real enterprise deployments across industries. By combining blockchain, IoT, ERP connectors, and analytics into a single framework, we give enterprises platforms that are both secure and practical at scale. This foundation is what allows us to move confidently into the next stage: guiding leaders through the exact steps required to develop and roll out a blockchain supply chain platform that doesn’t just work in pilot mode, but delivers lasting business impact.

How We Develop a Blockchain Supply Chain Platform

From our work at Intellivon, we’ve seen that successful blockchain platforms follow a disciplined approach. Through our development framework, we align business goals, secure adoption, and ensure the platform can scale. Here’s how we structure development.

1. Define Use Cases

The first step is identifying what the enterprise truly needs to solve. Counterfeit prevention, recall management, regulatory compliance, and supplier accountability are common drivers. Clarity here ensures the platform is purpose-built to deliver measurable outcomes, not a vague experiment.

2. Select the Right Framework

Not all blockchains are equal. For global supply chains, permissioned frameworks such as Hyperledger Fabric or Corda work best because they combine scalability, high transaction throughput, and strong governance. We match the framework to the enterprise’s operational and compliance landscape, so performance and trust go hand in hand.

3. Design the Data Model

Too many pilots fail because data structures don’t align with global standards. At Intellivon, we design every model around GS1 EPCIS, which guarantees interoperability with regulators, suppliers, and ERP systems. This makes integration smoother and reporting more reliable.

4. Build Strong Identity

Every actor in the supply chain must be verified, and every transaction must be attributable. Role-based identity ensures accountability at each stage, eliminating disputes over responsibility and strengthening trust between partners.

5. Integrate IoT Devices

Blockchain data must reflect what happens on the ground. By linking RFID tags, GPS trackers, and temperature sensors, we capture proof of movement and condition at every stage. These inputs are cryptographically secured, ensuring authenticity.

6. Automate Workflows

Smart contracts transform slow, manual processes into instant, verified actions. Payments can be released upon delivery confirmation, recalls can be triggered automatically, and compliance can be checked without human intervention. This reduces friction and accelerates operations.

7. Pilot and Stress Test

Before scaling, we run controlled pilots across a single product line or region. These allow us to test for performance, security, and compliance under real-world conditions, while keeping risk manageable.

8. Scale with Governance, Not Just Code

Technology alone doesn’t guarantee adoption. Scaling requires governance: defining who operates nodes, how upgrades are managed, and how disputes are resolved. We help enterprises build consortium rules that make the system sustainable long term.

Developing a blockchain supply chain platform is a staged journey, not a one-off project. By following this process, Intellivon ensures that platforms are secure, standards-compliant, and scalable from day one. With development in place, the next challenge lies in overcoming the real-world obstacles that often derail enterprise adoption — and building the solutions that keep projects on track.

Challenges Implementing Blockchain Supply Chain Platform and How We Overcame Them

Even the best-designed blockchain platforms encounter roadblocks during development and implementation. These are the same recurring issues that enterprises face when moving from concept to production. At Intellivon, we’ve seen them all, and we’ve built playbooks to address each one.

1. Data Quality and the Garbage-In Problem

Blockchain preserves whatever data you feed it. If a supplier enters the wrong batch number or a sensor misreports, those errors become permanent.

We fix this by enforcing data validation at the edge, where IoT devices are digitally signed, events are cross-verified, and transactions that don’t meet integrity thresholds are flagged before they reach the ledger. This ensures the blockchain records trusted data, not noise.

2. Partner Resistance and Partial Adoption

No platform delivers value if only a fraction of partners participate. Mid-tier suppliers often resist because they see blockchain as extra overhead.

Our approach is twofold: design lightweight mobile tools for smaller partners, and embed incentives such as faster payments or reduced compliance costs. This shifts blockchain from “extra work” to “business advantage.”

3. Real-Time Visibility Bottlenecks

Enterprises expect instant answers, like where a shipment is, whether it’s been stored within safe conditions, or which batches are at risk. Blockchains alone aren’t optimized for complex, high-speed queries.

To solve this, we use a hybrid architecture, which includes off-chain databases that handle fast queries, while cryptographic proofs keep the data anchored to the ledger. This gives executives immediate visibility without sacrificing trust.

4. Regulatory and Standards Alignment

Frameworks like the FDA’s DSCSA or the EU’s product passport rules leave no room for error. Many platforms fail because compliance wasn’t baked in early.

At Intellivon, we align every data model with GS1 EPCIS standards from day one, and run dry audits to confirm outputs match regulatory expectations before launch. This saves enterprises from costly retrofits and audit risks.

5. Balancing Privacy with Transparency

Enterprises want transparency without giving away sensitive details like pricing or sourcing agreements.

Our platforms solve this by using permissioned channels and selective disclosure, where each partner sees only what they need. Retailers can confirm product authenticity, regulators can validate compliance, and suppliers keep their commercial terms confidential.

6. Integration with Legacy Systems

Supply chains run on deeply embedded ERP, WMS, and transport systems. Forcing enterprises to replace them is unrealistic.

Intellivon uses middleware connectors and APIs to make blockchain the trust backbone, while existing systems remain the operational engines. This reduces resistance and accelerates adoption.

7. Governance and Node Management

Without clear governance, networks either centralize under one dominant player or stall due to indecision. We establish consortium charters defining who hosts nodes, how contracts are updated, and how disputes are resolved.

Governance smart contracts automate these rules, removing politics from daily operations.

8. Security Beyond the Ledger

The blockchain ledger may be tamper-proof, but surrounding applications are often the weak point. Dashboards, APIs, and smart contracts can still be attacked. That’s why we embed DevSecOps pipelines to scan and test every release before deployment, and use Runtime Application Self-Protection (RASP) to detect and block attacks in real time. Security is continuous, not reactive.

By combining edge validation, incentive-driven adoption, compliance alignment, hybrid architecture, and enterprise-grade security, we turn common pitfalls into competitive advantages. With these hurdles addressed, enterprises can focus on the outcome that matters most: building a secure, transparent, and future-ready supply chain.

How Do We Ensure Platform Privacy and Security

For enterprises, adopting blockchain isn’t only about visibility. The bigger question is trust: how do you protect sensitive business data while giving every partner the transparency they need? At Intellivon, we’ve designed our platforms with built-in guardrails that ensure security and privacy are never compromised.

1. Permissioned Networks

We don’t expose supply chain data on public chains. Our platforms run on permissioned blockchains where only verified organizations can participate. Every transaction is cryptographically signed, so there’s no doubt about who did what.

2. Tiered Data Privacy Controls

Not every participant should see every detail. We use channel-based privacy and selective disclosure to give partners access to the information they need, and nothing more. Retailers can confirm authenticity without seeing supplier pricing, and regulators can verify compliance without touching commercial contracts.

3. Anchoring Proofs, Not Payloads

High-volume files like IoT telemetry or certificates don’t sit directly on-chain. Instead, we anchor cryptographic proofs of these documents, ensuring data authenticity without bloating the ledger or exposing sensitive details.

4. Enterprise-Grade Security Standards

Our platforms align with strict frameworks such as GDPR, HIPAA, and SOC 2. We enforce end-to-end encryption, MFA, and role-based access controls, with nodes hardened to enterprise security standards.

5. Governance-Backed Trust

True security also depends on governance. Intellivon establishes clear rules for node operations, contract updates, and dispute resolution. This prevents centralization risks and builds long-term confidence in the platform.

6. DevSecOps Integration

Security isn’t an afterthought in our process. Every smart contract, API, and integration passes through continuous DevSecOps pipelines, with automated scans and penetration tests before production. This keeps vulnerabilities from slipping into live environments.

7. Runtime Protection with RASP

Even hardened applications can be targeted at runtime. Our platforms deploy Runtime Application Self-Protection (RASP) to monitor and block suspicious behavior inside applications, thereby stopping attacks before they reach the ledger.

For decision-makers, this seal of trust is what transforms blockchain from a risky experiment into a secure foundation for global operations.

Top Enterprises Using Blockchain Supply Chain Platforms

Blockchain supply chain platforms are not just theory — they are already delivering measurable results for some of the world’s largest enterprises. These cases demonstrate the kind of transformation that happens when blockchain is applied with the right strategy and scale.

1. Walmart + IBM Food Trust

Walmart partnered with IBM to build food traceability on blockchain. What once took seven days to trace the origin of mangoes now takes 2.2 seconds. The platform allows the retailer to run pinpoint recalls, reducing waste, cutting logistics costs, and strengthening consumer confidence in food safety. For a brand operating at Walmart’s scale, this translates into millions saved each year and faster compliance with food safety regulators.

2. De Beers (Tracr Platform)

The diamond industry has long faced questions of authenticity and ethical sourcing. De Beers created the Tracr blockchain platform to track stones from mine to retail. Each diamond receives a digital identity, and every step — cutting, polishing, certification — is logged. The result is 92% improved counterfeit prevention in high-value trade, strengthening brand reputation and consumer trust.

3. Volvo (EV Battery and Cobalt Traceability)

Volvo uses blockchain to track cobalt used in electric vehicle batteries. By recording sourcing and processing data immutably, the company ensures its batteries are free from conflict minerals and unethical labor practices. The initiative delivers real-time traceability of raw materials across multiple countries, helping Volvo meet regulatory demands and build consumer trust in its EV supply chain.

4. OpenSC (Sustainability Transparency)

OpenSC, a platform backed by WWF and BCG, focuses on making sustainability claims verifiable. Shoppers can scan a QR code on products and instantly access blockchain-verified information about sourcing and environmental impact. This approach has cut documentation processing times by 85% for suppliers, while offering end consumers visible proof of ESG commitments — a powerful differentiator in competitive markets.

5. IBM Blockchain (Cross-Industry Consortia)

IBM has rolled out blockchain platforms across industries, from logistics to manufacturing. Enterprises using IBM’s solutions report 20–30% cost reductions in supply chain operations, with disputes resolved faster due to shared, tamper-proof records. Tier 1 suppliers have rapidly integrated blockchain-powered ERP systems, with Infosys reporting 60% year-over-year growth in pilots moving into full production.

For enterprises, the question is no longer if blockchain works, but how quickly they can deploy it to secure similar advantages.

Conclusion

Blockchain supply chain platforms are proving to be far more than an emerging technology trend. They are quickly becoming the digital infrastructure enterprises need to operate with confidence in a global economy that demands transparency, speed, and compliance. By combining traceability, automation, and real-time visibility, these platforms reduce waste, prevent fraud, and turn regulatory challenges into opportunities for competitive differentiation.

For leaders evaluating the future of their supply chains, the message is clear: blockchain is no longer optional. It is the foundation for resilient, scalable, and trustworthy networks that can keep pace with global complexity. Enterprises that move early will not just save costs — they will secure market leadership in industries where trust and speed decide winners.

Build Your Blockchain Supply Chain Platform With Intellivon

At Intellivon, we design blockchain supply chain platforms that are built for enterprise realities, that are secure, compliant, and scalable from the ground up. Our approach doesn’t stop at technology. We bring together blockchain, IoT, ERP integration, and advanced analytics to create networks that deliver measurable ROI, faster compliance, and stronger partner trust.

Why Partner With Intellivon?

- Tailored Solutions: Every platform we design is aligned with your unique workflows, supply chain complexity, and regulatory requirements.

- Proven Expertise: From food safety to pharmaceuticals and luxury goods, we’ve delivered successful deployments that reduced costs and improved resilience.

- Security-First Design: DevSecOps, runtime protection (RASP), and governance frameworks are embedded into every solution we roll out.

- Future-Ready Architecture: Cloud-native, API-driven platforms that scale effortlessly as your operations and partnerships grow.

Book a discovery call with Intellivon’s blockchain engineers today and see how we can help you build a supply chain platform that delivers transparency, security, and growth at enterprise scale.

FAQs

Q1. What is a blockchain supply chain platform?

A1. A blockchain supply chain platform is a digital network that records every product movement, transaction, and verification step on a tamper-proof ledger. It enables real-time visibility, traceability, and compliance across all partners, reducing fraud and improving trust in global operations.

Q2. How does blockchain improve supply chain transparency?

A2. Blockchain creates a shared, immutable record of every event in the supply chain. This allows suppliers, logistics providers, retailers, and regulators to access the same verified information in real time, eliminating blind spots and disputes while making recalls and audits faster.

Q3. What are the key features of blockchain supply chain platforms?

A3. The most critical features include end-to-end traceability, chain-of-custody tracking, IoT integration, smart contract automation, permissioned privacy controls, audit readiness, and real-time analytics dashboards. Together, these features provide both operational efficiency and compliance assurance.

Q4. What challenges do enterprises face when implementing blockchain supply chains?

A4. Common challenges include poor data quality, resistance from partners, lack of standards alignment, privacy concerns, and integration with legacy systems. Enterprises overcome these by using GS1 standards, edge validation with IoT, hybrid architectures for scalability, and governance frameworks that define roles and rules.

Q5. Which companies are already using blockchain in supply chains?

A5. Walmart uses blockchain to trace food shipments in seconds instead of days. De Beers tracks diamond authenticity. Volvo verifies ethical cobalt sourcing for EV batteries. OpenSC provides sustainability transparency. IBM supports multiple industries with blockchain-powered platforms that reduce costs and disputes.